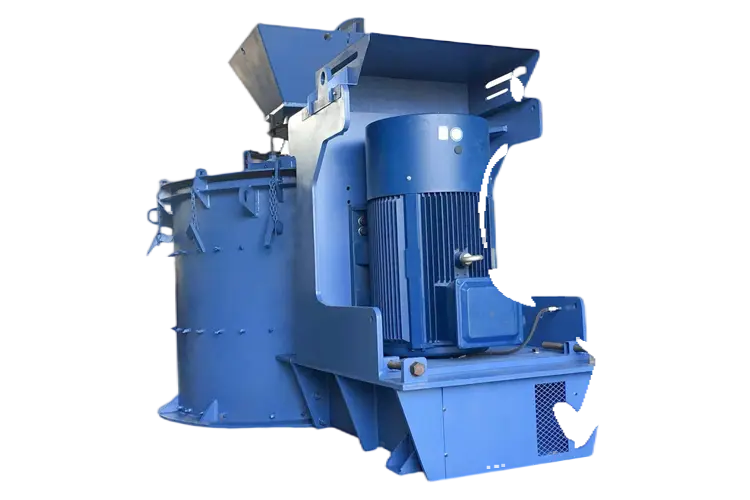

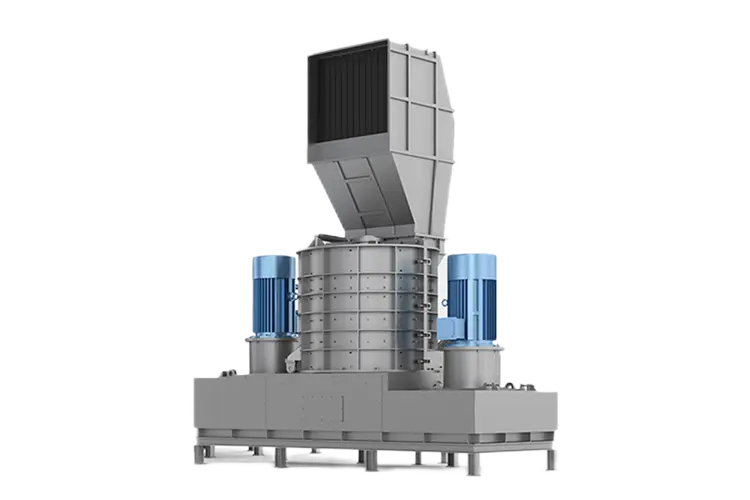

Vertical Compound Crusher – High-Efficiency Crushing & Sand-Making Solution for Diverse Industries

-

Core Advantages

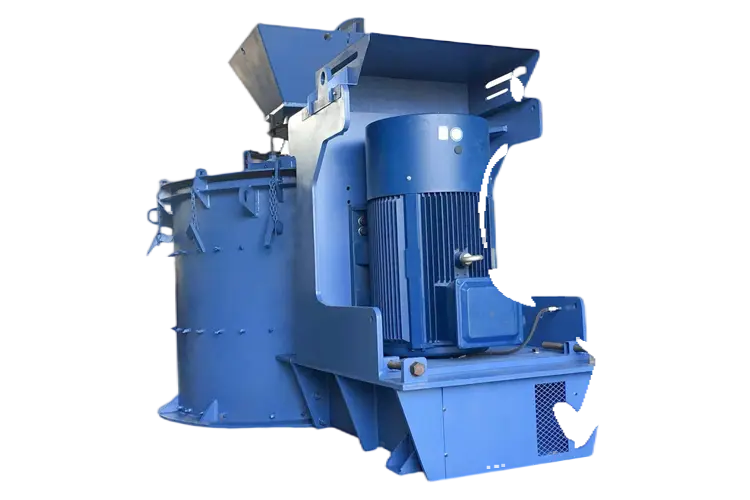

- Dual Functionality: Combines fine crushing and coarse grinding, saving equipment investment.

- Adjustable Output: Customize discharge particle size freely—no screen bars to avoid clogging, even with high-moisture or clay-rich materials.

- Easy Maintenance: Hydraulic opening device enables quick replacement of wear parts without major equipment disassembly.

- Eco-Friendly Design: Operates with noise below 75dB and minimal dust pollution, meeting green production standards.

-

Working Principle

- Materials vertically fall into the high-speed rotating impeller. Under centrifugal force, they collide at high speed with other materials distributed around the impeller. After mutual impacts, materials form a vortex between the impeller and casing, undergoing repeated collisions and friction. Finally, they are discharged from the lower part, achieving closed-circuit cycle crushing controlled by screening equipment to meet desired product sizes.

-

Main Features

- 1.High Crushing Ratio: Breaks large ore into medium-sized particles in one step, with adjustable discharge size.

- 2.Hydraulic Opening System: Rear cavity equipped with screw rod or hydraulic mechanism for effortless wear-part replacement.

- 3.Safety Assurance: Elastic adjustment mechanism automatically ejects uncrushable objects, protecting equipment from damage.

- 4.Durable Structure: Special rotor design ensures minimal wear during material crushing.

- 5.Green Operation: Low noise and dust emission for environmentally friendly production.

-

Applications

- Cement Industry: Fine crushing of raw materials and clinker.

- Mining: Processing dolomite, pyrophyllite, lead-zinc ore, serpentine, etc.

- Construction: Artificial sand production (hard limestone, dolomite, granite) and highway pavement stone crushing.

-

Take Action Now

- Ready to enhance your production efficiency?

- Request a Quote—Get customized solutions for your material processing needs.

- Download Catalog—Explore more details about our Vertical Compound Crusher.

- Contact Us—Our experts are here to support your project planning and technical inquiries.

Trust our Vertical Compound Crusher to deliver superior performance, durability, and eco-friendly operation for your industrial crushing needs!

Technical Parameters

| Specification | Processing Capacity (t/h) | Motor Power (kW) |

| 800 | 5–15 | 4P 30 |

| 1000 | 10–30 | 4P 55 |

| 1250 | 17–60 | 6P 132 |

| 1500 | 25–80 | 8P 160 |

| 1750 | 30–100 | 8P 200 |