Magnetic Levitation High-Speed Centrifugal Blower Helps Promote Green And Low-Carbon Development

In recent years, China has been promoting ecological civilization construction with unprecedented efforts, implementing a series of strategies, measures and actions to address climate change, participating in global climate governance, and promoting green and low - carbon development. As a result, energy conservation and emission reduction have become the focus of attention for various enterprises. In the operation of enterprises, choosing an energy - efficient and high - performance blower equipment can not only reduce the energy consumption and operating costs of enterprises, reduce their dependence on resources, and mitigate environmental impacts, but also enhance the corporate image and competitiveness. Against the backdrop of the national "dual - control of energy consumption" policy, high - energy - consuming industries will face pressure of production reduction or production bottlenecks. The adoption of energy - saving and environmentally friendly blower equipment is an inevitable trend.

This article will take you to a detailed interpretation of the advantages and application analysis of the magnetic levitation high - speed Centrifugal Blower. Let's take a look at how the magnetic levitation blower blows the green and low - carbon breeze.

The magnetic levitation high - speed centrifugal blower is a new type of high - efficiency, energy - saving and environmentally friendly blower formed by integrating magnetic levitation bearing technology and high - speed motor technology into traditional fans. It has significant features such as a simple structure, high - efficiency energy - saving, integration, easy operation and maintenance, and low operating costs. It can be widely applied in projects such as sewage treatment (municipal, industrial and others), material transportation, food and medicine, textile and dyeing, leather manufacturing, glass manufacturing, iron and steel metallurgy, and flue gas desulfurization, with remarkable energy - saving effects.

The high - efficiency impeller is designed with a three - dimensional flow design, and the five - axis machining technology ensures the manufacturing accuracy of the impeller, with good anti - corrosion performance.

The magnetic levitation bearings have no mechanical wear, do not require lubrication, and have a semi - permanent lifespan.

The high - power high - speed permanent - magnet synchronous motor has a small volume, light weight, and a high rotation speed, reaching up to 60,000 revolutions per minute.

It is convenient for installation and maintenance. It does not require a special foundation, is easy to maintain, does not need lubricating oil for maintenance, reduces the emission of pollutants such as waste oil, and reduces the use cost.

1. Advantages of the Magnetic Levitation Blower

• Energy - saving and high - efficiency: By using magnetic levitation bearings, there is no contact loss and mechanical loss, enabling stepless speed regulation at high speeds.

• High system integration: It is equipped with an inlet filter, cooling system, automatic anti - surge system, power - off and fault protection system, etc., bringing safety, convenience and reliability to operation.

• Low vibration and low noise: With the advanced magnetic levitation system and an integrated sound - proof cover, the rotating parts have no contact with the mechanical system, and the noise is less than 85 decibels.

2. Performance Comparison with Traditional Blowers

Performance comparison between the magnetic levitation high - speed centrifugal blower and traditional blowers (see Table 1).

Comparison Items Magnetic Levitation Blower Roots Blower

Fan Input Power 75KW 150KW

Overall Efficiency 85% 55%

Daily Operating Hours 24h 24h

Annual Power Consumption 648,000W/h 1,296,000kW/h

Annual Power Savings per Magnetic Levitation Blower 300,000 kWh -

(Table 1: Performance Comparison between Magnetic Levitation Blower and Traditional Blower)

In a waste treatment plant in Jinan, the original sewage tank aeration fans were three original Italian - imported Roots fans of RBS85/F type. The single - unit power was 75KW, with two in use and one in reserve. During normal production, two blowers ran at full load, and the actual total operating power calculated from data such as current and voltage was 144KW/h. There were problems such as high - temperature operation, high noise, high energy consumption of the sewage treatment aeration Roots fans, and the non - compliance of the aerobic value in sewage treatment.

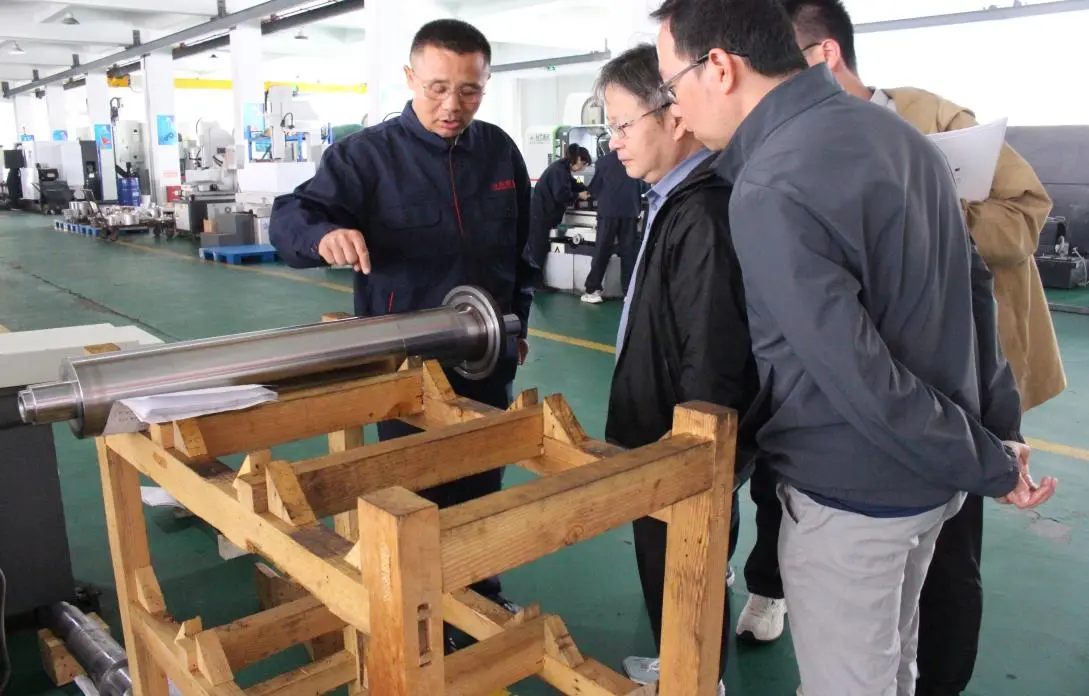

▲ Customer Site Picture

After summarizing the causes of the problems, Shandong Huadong Blower Co., Ltd. arranged technicians for on - site investigation, provided a technical transformation plan for the magnetic levitation blower. After reaching an agreement with the customer, the company quickly completed the equipment supply, installation and commissioning work to meet the on - site use requirements. After the transformation, the actual operating power of 103.3KW can meet the use requirements. The energy - saving rate of this transformation is as high as 28%, and it also reduces noise pollution and saves labor. This equipment does not need lubricating oil, is maintenance - free, and easy to operate.