In the world of mining and aggregate processing, the Gyratory Crusher plays a vital role. With its unique design, it crushes materials effectively, making it a preferred choice for many. Engineers and operators often seek the best models to enhance their operations.

Understanding the different Gyratory Crusher models is crucial. Each model offers various features and capabilities to handle diverse tasks. However, not all models are created equal. Some have advanced mechanisms, while others may lack essential functions.

This introduces a need for careful consideration and evaluation. What works for one application might not suit another. In this article, we will explore the top 10 Gyratory Crusher models. Each model has its strengths but also has areas that could use improvement. This discussion will aid in making informed decisions for optimal performance.

Gyratory crushers play a crucial role in mining and aggregate processes. They are designed for high-capacity applications, making them essential for large-scale operations. These machines excel at handling hard and abrasive materials, which often pose challenges in crushing operations. According to industry reports, the global gyratory crusher market is projected to reach a value of over $1 billion by 2027, growing at a compound annual growth rate of around 4.5%.

The application of gyratory crushers spans multiple sectors. They are commonly used in mining, quarrying, and recycling applications. Their ability to crush materials efficiently reduces operational costs. However, they are not without limitations. Maintenance can be intensive, and improper handling may lead to significant downtime. Additionally, selection of the right model is critical, as each design serves different material types and sizes.

The efficiency of a gyratory crusher largely depends on its design and application context. Operators must consider factors like feed size and material properties. Reports indicate that optimized configurations can improve throughput by up to 30%. Despite technological advancements, the human factor remains pivotal. Training and experience of the operators can significantly influence performance and safety outcomes. Careful planning and assessment are needed to avoid common pitfalls in operation.

Gyratory crushers are vital in the extraction and processing of minerals. They dominate large-scale mining operations due to their ability to handle high capacities. An essential feature is the crushing ratio, often ranging from 4:1 to 8:1. This ratio allows for significant material reduction in a single cycle.

Design differences significantly impact performance. The size of the discharge opening varies between models, which ensures adjustments for different material sizes. A larger opening increases throughput but may overwhelm the system. Another key feature is the eccentric throw, affecting fracture patterns and product shape. Higher eccentric throws enhance production but may lead to faster wear.

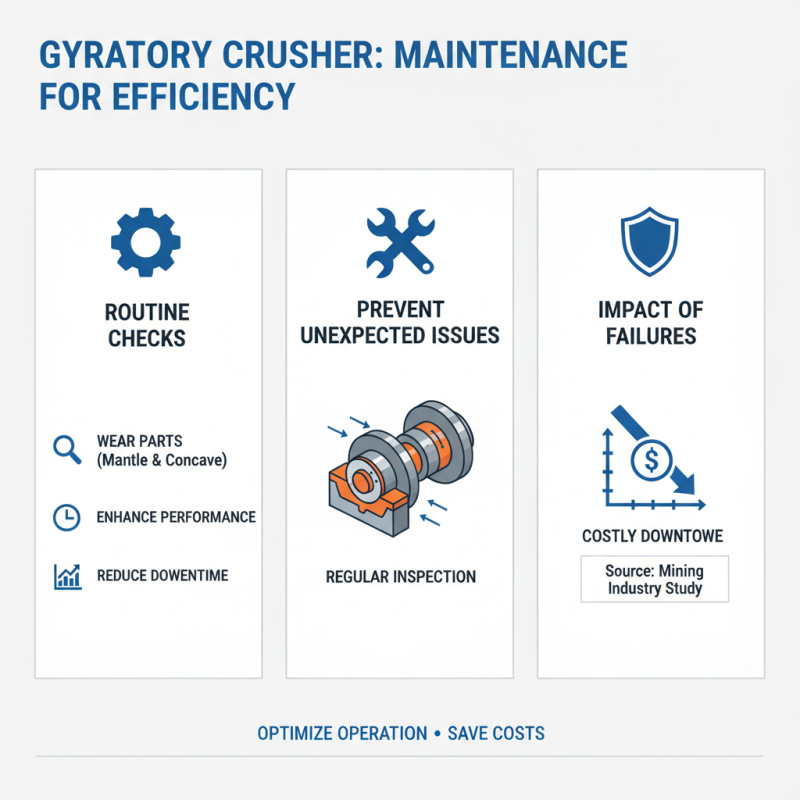

Maintenance plays a critical role. Regular inspections and part replacements are necessary. Inadequate maintenance can lead to costly downtimes. Industry reports show that proper maintenance can reduce operational costs by 15%. Operators often overlook this, focusing more on capacity than longevity. Understanding these nuances can distinguish successful operations from struggling ones.

| Model | Capacity (TPH) | Max Feed Size (mm) | Motor Power (kW) | Weight (kg) |

|---|---|---|---|---|

| Model A | 400 | 150 | 132 | 24000 |

| Model B | 700 | 180 | 160 | 30000 |

| Model C | 600 | 160 | 150 | 25000 |

| Model D | 800 | 200 | 180 | 32000 |

| Model E | 500 | 140 | 110 | 22000 |

| Model F | 650 | 175 | 155 | 29000 |

| Model G | 720 | 185 | 170 | 31000 |

| Model H | 900 | 210 | 200 | 35000 |

| Model I | 550 | 155 | 140 | 26000 |

| Model J | 750 | 195 | 175 | 33000 |

Gyratory crushers play a crucial role in the mining and aggregate industry. There are various models available, each designed for specific needs. These models differ in size, capacity, and design features. When selecting a gyratory crusher, it’s essential to consider the machine's specifications and how they align with your project requirements.

For instance, some models may focus more on throughput while others prioritize energy efficiency. The operational speed, crushing chamber shape, and material specifications also matter. A well-chosen model can enhance productivity. However, choosing the wrong unit can lead to inefficiencies and increased operating costs. It’s vital to review the data thoroughly before making a decision.

Additionally, maintenance is often overlooked. Some models require frequent inspections or part replacements. Ignoring these needs can result in unexpected downtimes. Proper selection and ongoing upkeep are necessary to maximize the performance of any chosen gyratory crusher. It is wise to reflect on both current and future needs when making your choice.

When selecting a gyratory crusher, performance metrics are critical. Key metrics include throughput, energy efficiency, and particle size distribution. A recent industry report indicates that the average throughput for modern gyratory crushers ranges from 2,500 to 5,000 tons per hour. This data demonstrates a significant improvement in efficiency over older models.

Another important performance metric is energy consumption. The best models operate at an efficiency of around 90%. However, some units still fall short, consuming up to 15% more energy than necessary. This discrepancy can lead to higher operational costs and a larger carbon footprint. Attention to energy-rating criteria is essential for sustainable operations.

Tip: Always compare energy efficiency ratings before purchasing. Small differences can amount to huge savings over time.

Particle size distribution is also vital. An ideal gyratory crusher can produce a consistent output size, reducing the need for further processing. However, inconsistencies in design may lead to irregular output sizes. This can affect downstream processes and overall productivity.

Tip: Regular maintenance checks can help identify issues early, ensuring optimal performance.

Maintaining a gyratory crusher is crucial for its efficient operation. Routine checks on wear parts can significantly enhance performance. A study from the Mining Industry shows that equipment failures can lead to costly downtime. Regularly inspecting components like the mantle and concave can prevent unexpected issues.

Tips: Always keep a maintenance log. Document each inspection, noting any wear and tear. This practice helps identify patterns over time.

Moreover, proper lubrication is essential. According to industry guidelines, maintaining recommended lubricant types and levels can extend the crusher's lifespan. Insufficient lubrication may cause overheating. This could lead to severe damage and increased repair costs.

Tips: Use a reliable system for monitoring oil levels. Automated systems can alert you of low lubricant levels in real time.

Also, track the performance metrics carefully. Unexpected changes can indicate underlying problems. Regular recalibration of the instrumentations is key. Workers should feel empowered to report odd noises or vibrations. This culture of vigilance enhances operational efficiency.