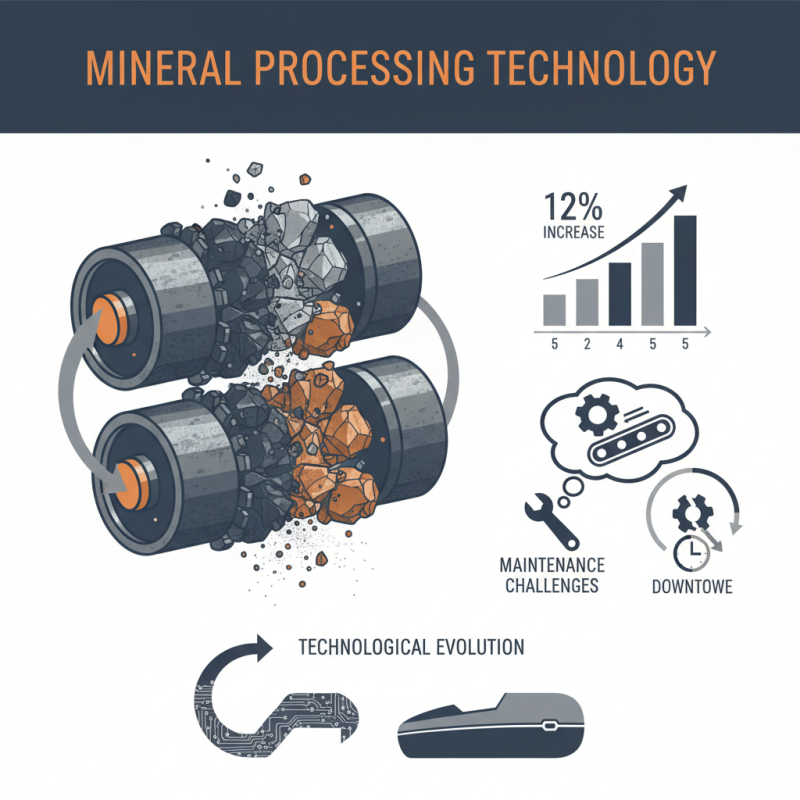

In the world of mineral processing, roll crushers play a crucial role. These machines are designed to crush various materials, including coal, limestone, and ores. According to a report by the Global Mining Equipment Market, the demand for roll crushers has surged by 12% over the last five years. This increase reflects their efficiency and effectiveness in size reduction applications.

Dr. John Smith, a leading expert in crushers, once noted, "Roll crushers provide a reliable solution for high-volume crushing." This statement highlights the importance of these machines in industrial settings. Roll crushers work by compressing materials between two rotating cylinders. This design minimizes dust and improves efficiency compared to other crushing methods.

However, the use of roll crushers isn’t without challenges. The wear on the rolls can lead to costly downtime. Proper maintenance is essential to ensure reliability. While these machines are useful, users must remain aware of their limitations and stay proactive about potential issues. The evolution of technology in this sector continues to shape how we view roll crushers.

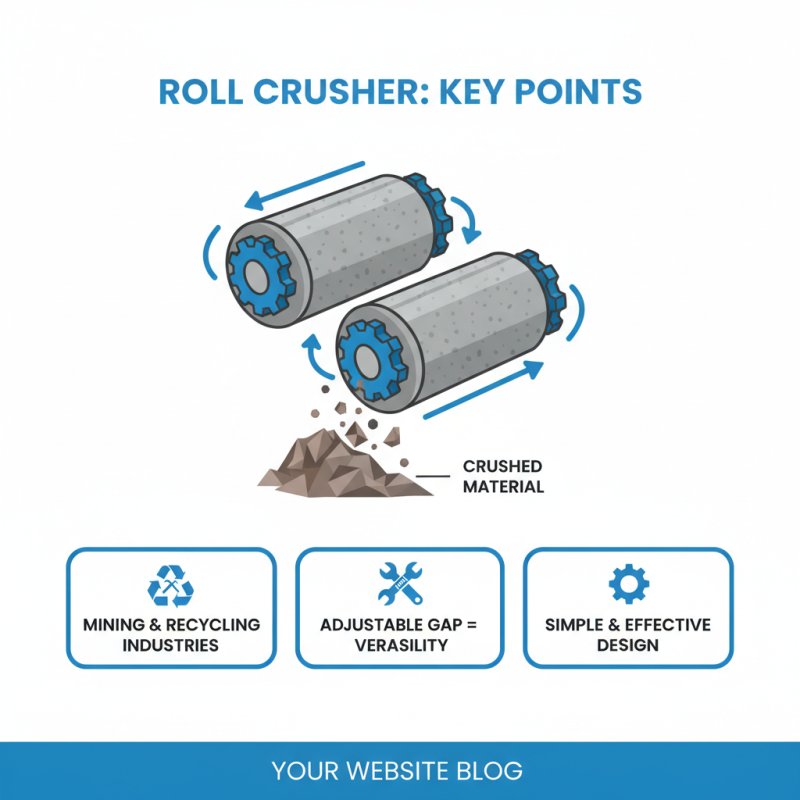

A roll crusher is a type of crushing machine. It uses cylindrical rollers to crush materials. These machines are commonly used in mining and recycling industries. Their design is simple yet effective. Two rotating rollers work together to break down materials. The gap between the rollers can be adjusted for different sizes. This feature makes roll crushers versatile.

These crushers handle a variety of materials, including minerals and coal. They can crush materials into smaller, more manageable pieces. The process is relatively quiet compared to other machines. However, they can experience wear and tear over time. Regular maintenance is essential to keep them running efficiently. Operators must pay close attention to any signs of damage.

One important aspect is the feed size. Materials fed into a roll crusher must be consistent. If not, uneven crushing may occur. This can lead to inefficiencies in the crushing process. It's also crucial to monitor the output size. A poorly adjusted gap can result in oversized or undersized particles. This reflects the importance of operator training and awareness.

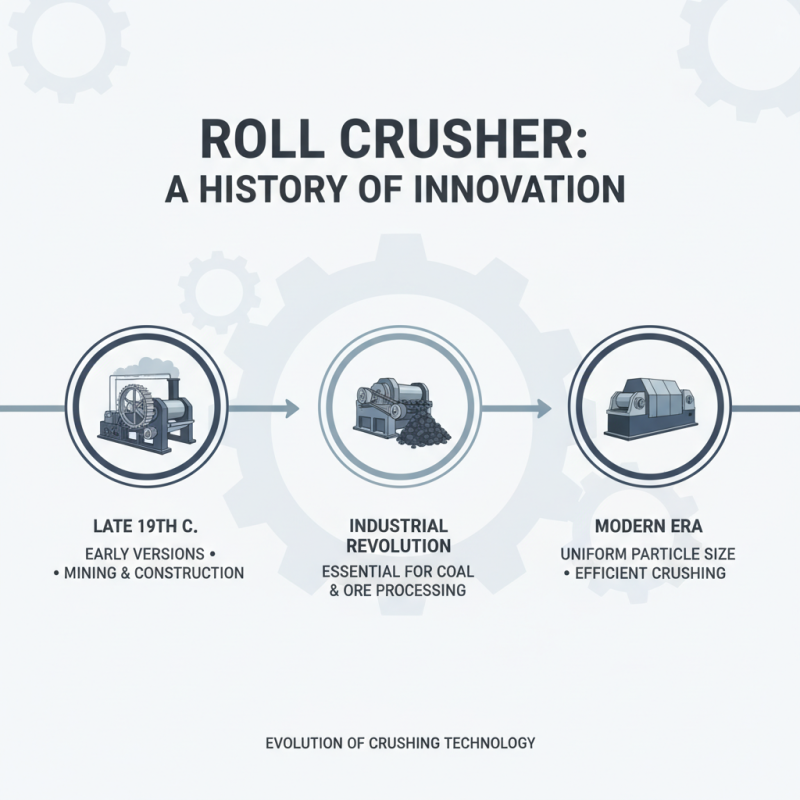

The roll crusher has a rich historical background. Early versions appeared in the late 19th century. Inventors sought efficient ways to crush materials for mining and construction. These machines became essential for processing coal and ores. They were favored for their ability to produce uniform particle sizes.

Initially powered by steam, these machines evolved quickly. As the industrial revolution gained momentum, innovations improved their design. The introduction of electric drives made roll crushers more efficient. By the early 20th century, they were widely used in various industries. Yet, many designs appeared flawed through the years, leading to inefficiencies.

As technology progressed, engineers made adjustments. Different configurations emerged to tackle various materials. However, not all solutions were perfect. Some designs struggled with durability and wear. Reflecting on these challenges highlights the importance of ongoing innovation. Roll crushers evolved but still faced limitations. They remind us that even widely used technology requires continual improvement.

Roll crushers play a vital role in material processing within industries like mining and aggregates. They function by compressing material between two rotating cylinders or rolls. This action crushes the material into smaller, uniform sizes. According to industry reports, roll crushers can achieve reduction ratios of up to 4:1, making them efficient for various applications.

The operational principle of roll crushers hinges on the adjustable gap between the rolls. By modifying this gap, operators can control the size of the output material. For example, a narrower gap produces finer materials, which is pivotal in industries requiring precision. However, optimization can be tricky. An incorrect gap setting might result in excessive fines or oversize material, leading to inefficiencies.

In practice, maintaining the right balance between power consumption and throughput is essential. Reports from mining studies indicate that improperly configured roll crushers can waste up to 25% of energy. Regular maintenance helps prevent wear and prolong the life of the rolls, but it requires diligence. Continuous monitoring is crucial to avoid unexpected breakdowns and ensure consistent production quality.

Roll crushers are essential in various industries. They are designed to crush materials between two rotating rollers. These machines handle different materials effectively, making them versatile tools in the processing world.

There are several types of roll crushers available. For instance, single roll crushers use one roller to crush the material against a solid surface. They are ideal for soft to medium materials. In contrast, double roll crushers feature two rollers. They excel in handling tougher, more abrasive substances. They can achieve finer product sizes too.

Some applications include coal, limestone, and metal ores processing. Yet, roll crushers may not perform well with all materials. Certain designs lead to wear and tear. Operators must consider maintenance carefully. If not done, efficiency drops. Each type has its limitations. It’s essential to assess the specific needs before choosing a roll crusher.

Roll crushers are popular in mineral processing. They work by compressing material between two rotating rolls. This method is effective for reducing the size of various minerals and aggregates. Their design allows for high throughput and consistent output size.

One significant advantage of roll crushers is that they produce less fine material. This is beneficial for companies looking to achieve specific size distributions. They are also relatively easy to operate and maintain. However, roll crushers come with limitations. For instance, they are not suitable for all types of materials. Hard and brittle substances may not crush effectively. Additionally, the operational capacity is limited compared to other crushers.

Operators should consider the material being processed. Roll crushers may require adjustments for optimal performance. It's essential to monitor wear on the rolls. Regular maintenance can help achieve better efficiency. Ultimately, while roll crushers offer advantages, one must also evaluate their limitations in processing diverse materials.