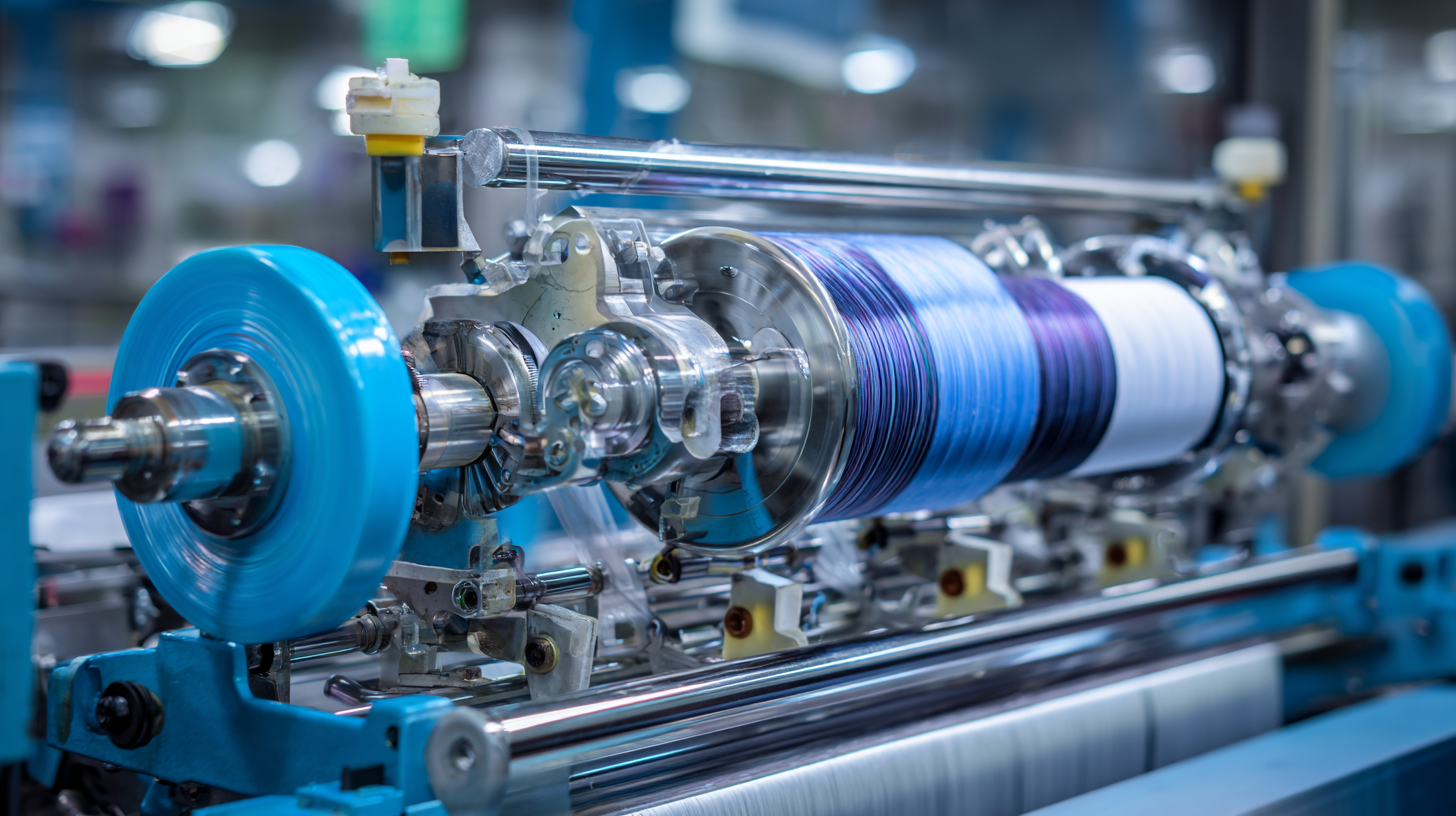

The textile industry is undergoing a significant transformation, driven by advanced technologies that enhance production efficiency and sustainability. Among these innovations, the Textile Machine Roller Sleeve has emerged as a crucial component in modern textile manufacturing, optimizing the way fibers are processed and developed into finished products. According to a recent report by the International Textile Manufacturers Federation (ITMF), the global textile machinery market is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, highlighting the increasing demand for sophisticated machinery that can streamline operations. Additionally, the use of advanced roller sleeve technologies not only reduces material waste but also increases the lifespan of machines, contributing to long-term cost savings and environmental sustainability. As manufacturers seek to remain competitive in a rapidly evolving marketplace, the integration of high-performance Textile Machine Roller Sleeves will play a pivotal role in revolutionizing textile production.

Advanced roller sleeve technologies are transforming the textile production landscape, enhancing efficiency and product quality. According to a recent report by Textile World, manufacturers utilizing these technologies have seen a reduction in production downtime by up to 30%. This significant improvement is primarily due to the ability of advanced roller sleeves to promote faster and smoother fabric handling, leading to less wear and tear on machines.

Using smart materials and innovative design, modern roller sleeve technologies are designed to optimize the application of dyes and finishes, resulting in better color consistency and reduced chemical waste. A study conducted by the European Textile and Apparel Association revealed that facilities implementing these advancements reported up to 25% savings in dye usage, contributing to more sustainable production practices.

**Tip:** When considering the integration of advanced roller sleeves, thorough training for your team is essential to maximize the benefits. Regular maintenance checks also help ensure optimal performance and longevity of the rollers. Investing in these technologies not only boosts production efficiency but also aligns with the industry's growing trend toward sustainability and waste reduction.

The textile industry is witnessing a remarkable transformation with the advent of advanced roller sleeve technologies, which are proving to be pivotal in modern manufacturing. These technologies optimize the printing and dyeing processes, significantly enhancing productivity. According to a recent report by the International Textile and Apparel Association, manufacturers adopting roller sleeve technologies have reported a reduction in downtime by up to 30%, which translates to a more efficient operation and a quicker turnaround time for products.

Moreover, the implementation of roller sleeve technologies leads to superior consistency and quality in the finished textile products. A study conducted by Textile World found that these advanced systems can improve color accuracy by nearly 25%, ensuring that the final output meets rigorous quality standards. This accuracy not only enhances customer satisfaction but also reduces the amount of waste associated with rework and overproduction, thus promoting a more sustainable approach to textile manufacturing. Adopting such innovative technologies is not just a competitive advantage; it is becoming essential for businesses aiming for long-term success in the dynamic textile market.

This chart illustrates the key benefits of implementing advanced roller sleeve technologies in textile manufacturing, focusing on efficiency, cost reduction, and product quality enhancements.

Integrating advanced roller sleeve technologies in textile production requires a systematic approach to ensure a seamless transition and optimized performance. Begin by assessing your current manufacturing processes to identify specific needs and challenges that roller sleeves can address. This assessment will guide the selection of the right roller sleeve system tailored to your facility’s unique requirements. Furthermore, consider the potential integration of artificial intelligence to enhance production efficiency. AI can aid in predictive maintenance, inventory management, and process optimization, ensuring that your roller sleeve systems operate at peak efficiency.

Once you have chosen the appropriate roller sleeve technology, develop a step-by-step implementation plan. Start with employee training to familiarize your team with the new systems, emphasizing the benefits of enhanced productivity and reduced downtime. Next, gradually phase in the roller sleeve systems, monitoring performance closely and making adjustments as necessary. Utilizing real-time data analytics can help refine operations further, identifying patterns and areas for continuous improvement. By leveraging advanced technologies alongside roller sleeve systems, textile manufacturers can revolutionize their production processes, driving significant improvements in both quality and output.

The textile industry is experiencing a significant transformation due to the innovative applications of advanced roller sleeve technologies. These technologies not only enhance the efficiency of fabric production but also improve the quality of the final products. According to a report by the Global Smart Textiles Market, the adoption of such technologies can reduce production time by up to 30%, allowing manufacturers to meet increasing demands while maintaining high standards.

One of the breakthrough applications of roller sleeve technologies lies in digital printing. By employing customizable roller sleeves, textile producers can achieve intricate designs with optimal precision and minimal waste. This method streamlines the printing process, enabling companies to launch seasonal collections with shorter lead times. Additionally, the integration of automation with roller sleeve technology contributes to consistent quality, reducing variability often seen with traditional methods.

**Tip:** When considering roller sleeve solutions, assess the compatibility with existing printing equipment to maximize efficiency.

Moreover, the adaptability of roller sleeve technologies allows for the incorporation of sustainable practices, such as using eco-friendly inks and reducing material waste in the production line. This trend aligns with the increasing consumer demand for environmentally responsible textile production. According to the Sustainable Apparel Coalition, brands leveraging these innovative technologies report a 25% reduction in overall resource usage, paving the way for a greener future in textiles.

**Tip:** Explore various materials and finishes that roller sleeves can accommodate to diversify your product offerings.

| Application Area | Technology Type | Benefits | Market Impact |

|---|---|---|---|

| Coating | Nano-coating Rollers | Enhanced durability, water resistance | Increased product lifespan and reduced waste |

| Printing | Digital Roller Printing | High precision, reduced ink usage | Boosted customization and reduced turnaround time |

| Finishing | Heat Transfer Rollers | Improved texture and softness | Enhanced consumer satisfaction and product appeal |

| Recycling | Recycling Rollers | Facilitates the recycling of textile waste | Reduced environmental impact and sustainability |

The textile industry is undergoing a significant transformation, primarily driven by advancements in roller sleeve technologies. According to a recent report by Markets and Markets, the global textile market is expected to grow from $1,020 billion in 2021 to $1,400 billion by 2028, representing a CAGR of approximately 4.5%. With the adoption of innovative roller sleeve systems, manufacturers can enhance production efficiency and reduce waste, making it easier to respond to evolving consumer demands for sustainable and high-quality products.

Future trends in textile production indicate that technical innovations in roller sleeves will play a crucial role in achieving these goals. An analysis by Technavio suggests that the increased focus on automation and digitization in textile manufacturing will contribute significantly to market growth, with roller sleeve technology potentially reducing machine downtime by up to 30%. Furthermore, advancements in materials science are allowing for the development of roller sleeves that are not only more durable but also capable of handling a wider variety of fabrics and finishes, paving the way for more versatile production capabilities.