In today's rapidly evolving industrial landscape, maximizing efficiency has become a top priority for manufacturers striving for competitive advantage. Permanent Magnet Direct Drive Motors (PMDDMs) have emerged as a pivotal technology in this quest, offering superior performance and enhanced energy efficiency compared to traditional motor systems. According to recent industry reports, PMDDMs can improve overall system efficiency by up to 30%, significantly reducing operational costs and energy consumption. Furthermore, these motors contribute to lower maintenance requirements and extended service life, making them a reliable choice for various applications, from robotics to conveyor systems. As companies look to optimize their processes and adhere to stricter regulatory standards regarding energy usage, understanding how to effectively implement PMDDMs will be essential for driving operational excellence and sustainability in manufacturing.

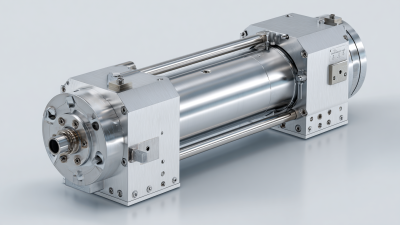

Permanent Magnet Direct Drive Motors (PMDDMs) are increasingly recognized for their efficiency and effectiveness in various applications ranging from industrial machinery to electric vehicles. At their core, PMDDMs utilize permanent magnets to create a magnetic field, which eliminates the need for brushes and gears traditionally found in other motor types. This direct drive mechanism significantly reduces friction and enhances performance, making it an ideal choice for applications requiring high precision and reliability.

When considering the integration of PMDDMs into your operations, it’s crucial to focus on a few key tips. First, evaluate your application’s specific torque and speed requirements to ensure that the selected motor will deliver optimal performance. Additionally, choose motors that are designed with a high-quality thermal management system to maintain efficiency during prolonged use. Lastly, regular maintenance and monitoring can extend the lifespan of these motors and ensure consistent operation.

Another important aspect to consider is the compatibility of PMDDMs with your existing systems. Implementing efficient drive controllers specifically designed for PMDDMs can maximize their potential and enhance overall system efficiency. By understanding the basics and considering these tips, you can effectively leverage the benefits of Permanent Magnet Direct Drive Motors in your operations.

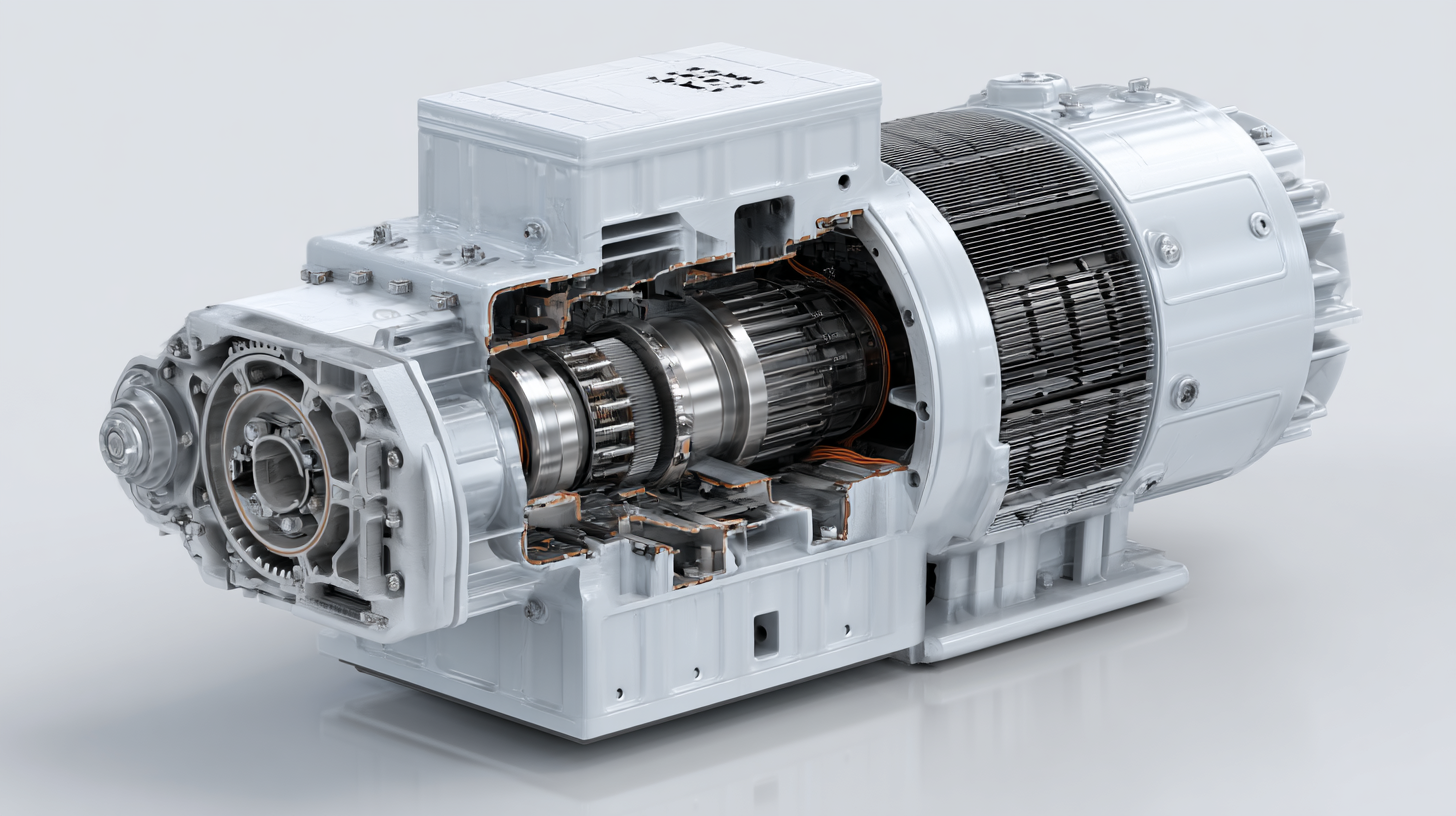

Permanent Magnet Direct Drive Motors (PMDDMs) offer significant advantages that align with the growing demand for efficient and sustainable energy solutions in various industries. One of the key benefits of these motors is their high efficiency, typically exceeding 90% under optimal conditions. According to a report by the International Energy Agency (IEA), adopting high-efficiency motors, like PMDDMs, can lead to energy savings of up to 20% in industrial applications, contributing to lower operational costs and reduced carbon footprints.

Additionally, PMDDMs excel in torque density and responsiveness, making them ideal for applications requiring precise control and rapid acceleration. A study by the Department of Energy (DOE) indicates that PMDDMs can provide up to 60% more torque than traditional induction motors of the same size, enabling more compact designs and improved overall system performance. This characteristic not only enhances productivity but also reduces the size and weight of machinery, a crucial factor in sectors such as automotive and aerospace, where space and weight efficiency are paramount. The integration of PMDDMs is a strategic move toward maximizing efficiency and achieving sustainability goals in today’s competitive landscape.

When it comes to maximizing efficiency with permanent magnet direct drive motors, proper installation and maintenance are crucial. To ensure optimal performance, it is recommended to follow best practices during the installation phase. First, ensure that the mounting surfaces are clean and level, as any misalignment can lead to mechanical stress and decreased efficiency. Additionally, using the correct size and type of couplings can help mitigate vibration and enhance overall system reliability.

Tips:

1. Regularly check the alignment of the motor with the driven equipment to prevent wear and tear.

2. Implement a lubrication schedule based on the manufacturer's guidelines to keep bearings in optimal condition.

Maintenance is equally important in maximizing the longevity of direct drive motors. Establish a routine inspection schedule to monitor for any signs of wear or abnormal sounds. Cleaning the motor and surrounding area can also help prevent dust and debris from causing operational issues. Moreover, monitoring temperature variations can provide insights into potential problems before they become critical.

Tips:

1. Set up vibration analysis to detect early signs of bearing failure or misalignment.

2. Use thermal imaging to identify overheating issues that could impact performance.

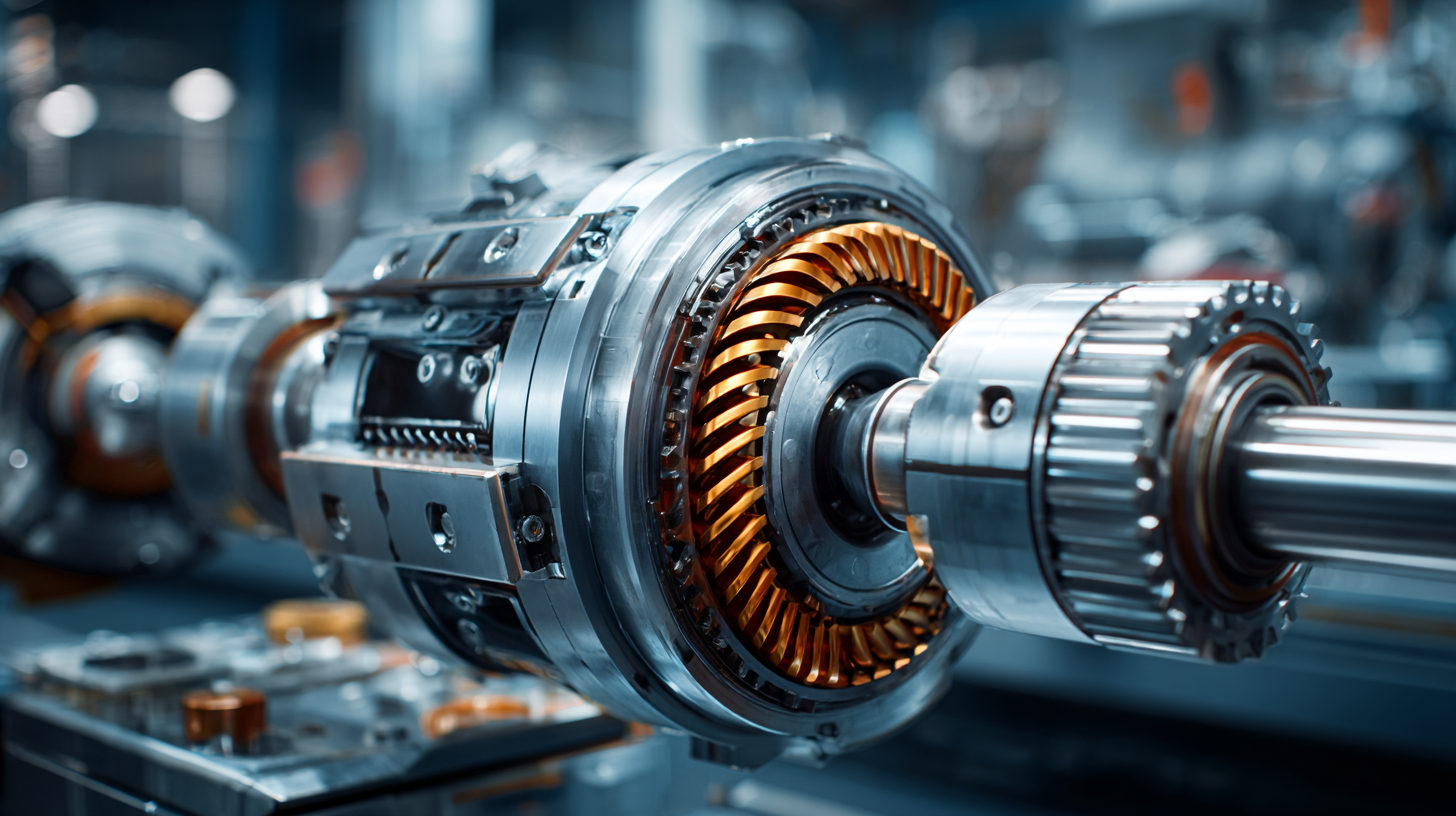

The optimization of performance and efficiency in motor applications, particularly with Permanent Magnet Direct Drive Motors (PMDDMs), can be significantly enhanced through innovative technologies and methods. Recent advancements in simulation tools such as CAE (Computer-Aided Engineering) are paving the way for improved designs that meet the increasingly stringent performance requirements in sectors like electric vehicles. By integrating CAE with AI, the development cycle for motor systems can be accelerated, allowing for enhanced predictive capabilities that lead to better overall efficiency and performance.

In the context of electric vehicles, maximizing efficiency with PMDDMs is crucial, especially as the industry anticipates sustained growth in production and demand. By focusing on energy recovery strategies, like regenerative braking and optimizing the control strategies for motor operation, manufacturers can significantly improve the energy utilization of their systems. Furthermore, advancements in materials and manufacturing processes for axis flux motors are also playing a vital role in achieving higher power density and efficiency in direct drive applications, making them more competitive in the evolving automotive landscape.

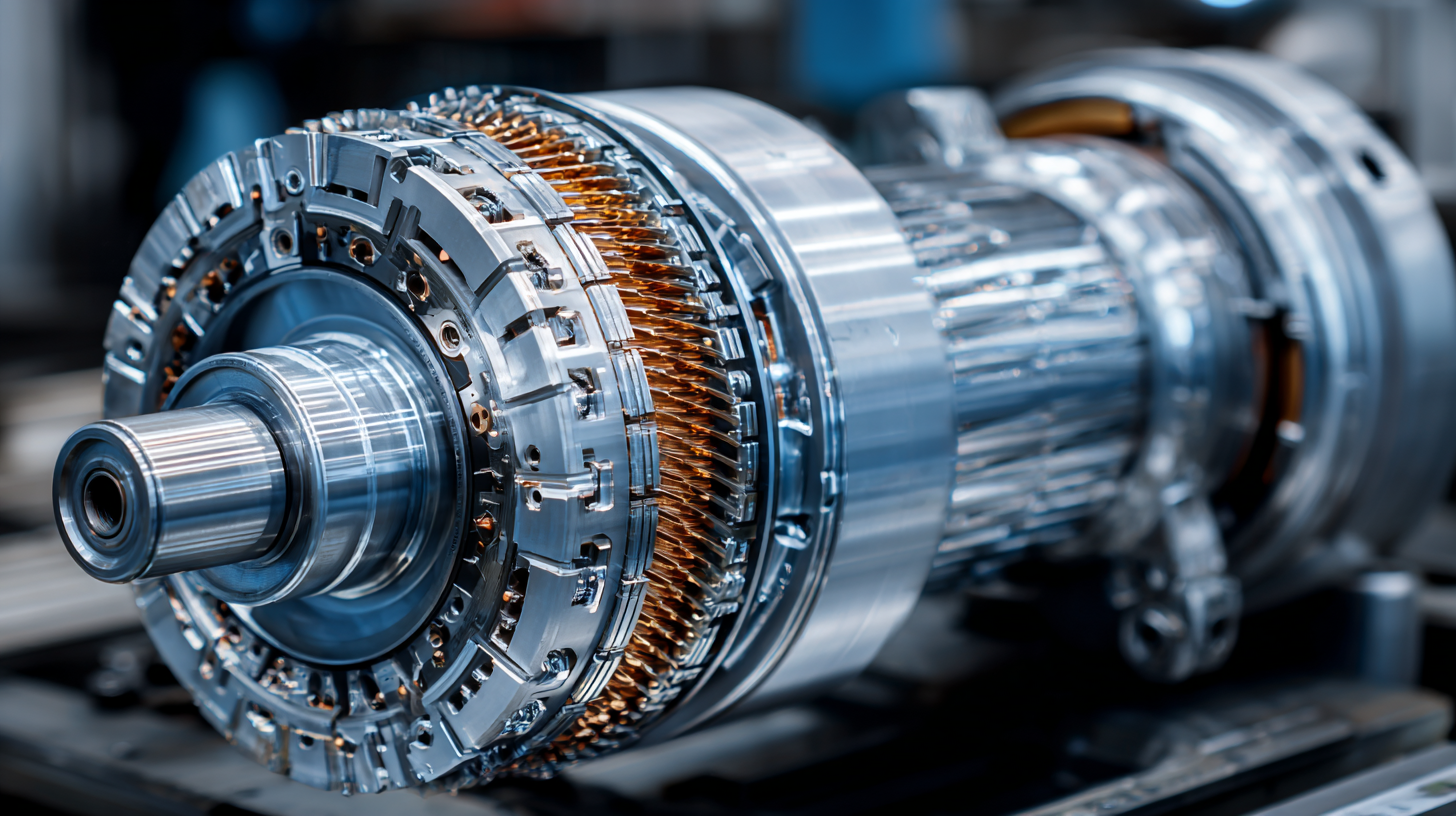

In recent years, permanent magnet direct drive (PMDD) motors have gained popularity due to their ability to deliver high efficiency and superior performance in various applications. To further enhance the operation of direct drive systems, innovative control strategies have become a focal point of research and development. According to a report by a leading industry analyst, integrating advanced control algorithms can improve the system's overall efficiency by up to 20%, significantly reducing energy consumption in industrial operations.

One notable approach involves the implementation of predictive control techniques, which analyze historical data and system behavior to optimize motor performance in real-time. This strategy allows for precise adjustments to the motor's power output, adapting to varying load conditions and operational requirements. Additionally, sensorless control methods, which eliminate the need for physical sensors, can reduce component costs and increase system reliability. As highlighted by a study from the International Journal of Electrical Engineering, these innovative methods have the potential to enhance the accuracy of torque and speed control, facilitating better performance in applications such as robotics and renewable energy systems.

Furthermore, advancements in machine learning algorithms are paving the way for adaptive control strategies that can learn from changes in system dynamics and environment, ensuring peak performance under all conditions. As the demand for efficient and reliable direct drive systems continues to rise, these innovative control strategies will be critical in shaping the future of PMDD motor applications.