Understanding PM Synchronous Motors is crucial for many industries today. According to Dr. Emily Carter, a well-regarded expert in electric machinery, “PM Synchronous Motors offer efficiency and precision that are hard to match.” This insight highlights the growing importance of these motors in modern applications.

PM Synchronous Motors utilize permanent magnets to produce a constant magnetic field. They are known for their high efficiency and reliability. However, not all applications may find them suitable. For example, the cost of initial setup can be a significant factor.

Exploring the characteristics of PM Synchronous Motors reveals their unique benefits. These motors operate at a constant speed, which enhances performance in various settings. Yet, they also require careful consideration regarding control systems and power supply. A deeper understanding can help engineers make better design choices, despite the complexities involved.

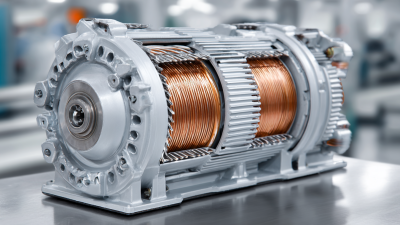

A Permanent Magnet (PM) Synchronous Motor is a type of electric motor that uses magnets instead of windings to generate a magnetic field. This design makes it highly efficient. In fact, studies indicate that PM synchronous motors can achieve efficiencies of over 95%. The operating principle is simple: the rotor, equipped with permanent magnets, synchronizes with the rotating magnetic field produced by the stator.

These motors work best in applications requiring precise speed and position control. For instance, in automation, they can enhance performance and reduce energy consumption. The ability to maintain a constant speed under varying loads is crucial for many industries, such as manufacturing and robotics. However, the initial cost can be higher than other motor types, leading to debates about long-term ROI.

The control of PM motors can be complex. It often requires sophisticated drive systems and controllers. This adds layers of complexity to their implementation. As industries adopt these motors, the need for skilled personnel to manage and troubleshoot them becomes evident. There are ongoing discussions about the balance between efficiency and ease of use in PM synchronous motors.

| Dimension | Description |

|---|---|

| Operating Principle | Utilizes permanent magnets in rotor and stator to create a constant magnetic field, ensuring synchronous speed with the frequency of the supply current. |

| Efficiency | High efficiency typically ranging from 85% to 95% due to low copper losses and high quality of components. |

| Applications | Commonly used in robotics, electric vehicles, and various industrial applications requiring precise speed and position control. |

| Advantages | Lower maintenance, higher power factor, and compact design compared to induction motors. |

| Disadvantages | Higher initial cost and complexity in control systems. |

| Control Methods | Typically controlled using advanced techniques such as Field-Oriented Control (FOC) for improved performance. |

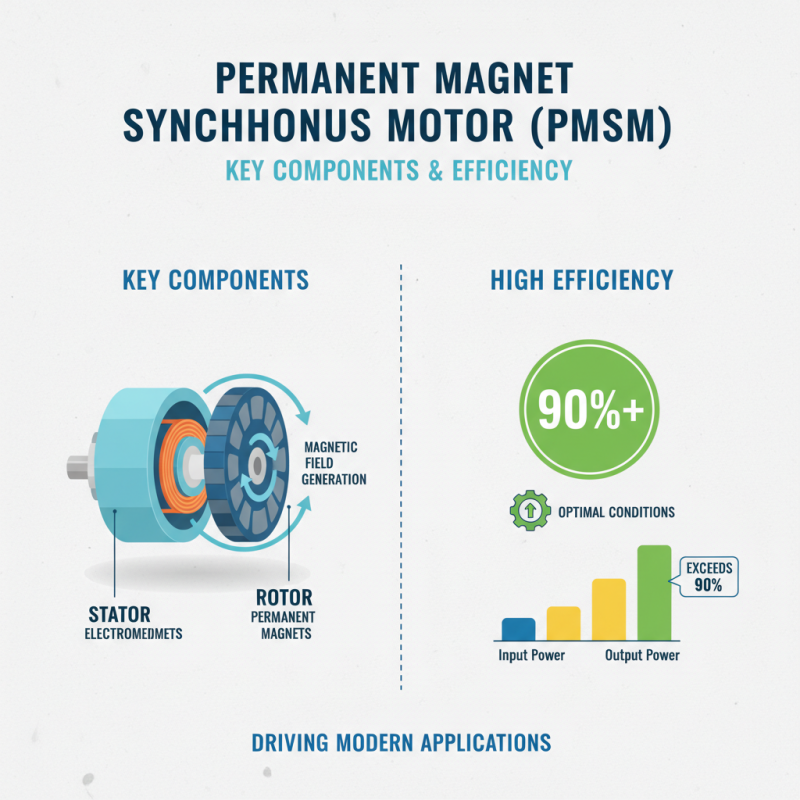

Permanent magnet (PM) synchronous motors are widely used in various applications. Key components drive their effectiveness. The rotor, embedded with permanent magnets, generates a consistent magnetic field. This design aids in achieving high efficiency, often exceeding 90% in optimal conditions.

The stator, with its windings, plays a crucial role. When AC voltage is applied, it creates a rotating magnetic field. According to a recent report by the International Energy Agency, these motors can save up to 30% more energy than conventional induction motors. This efficiency is essential for industries seeking to reduce operational costs and carbon footprints.

Control systems also deserve mention. They manage speed and torque through precise adjustments. However, challenges exist in the integration of these systems. Sometimes, users undervalue the complexity of tuning the drive settings. An improper setup can negate efficiency gains. Regular updates and assessments are vital for maintaining performance in PM synchronous motors.

Permanent Magnet (PM) Synchronous Motors offer several advantages in various applications. Their efficiency is remarkable. Research indicates that these motors can operate with efficiency levels exceeding 90%. This makes them ideal for applications where energy conservation is critical. In industrial settings, their ability to maintain constant speed under varying loads is beneficial.

Moreover, PM Synchronous Motors require less maintenance compared to traditional induction motors. This results from their simple construction. Fewer moving parts typically lead to fewer failures. However, the challenge lies in their initial cost. They can be more expensive to purchase. Many businesses might hesitate because of this upfront investment.

Another key benefit is their compact size. In a world where space is often limited, these motors can fit easily into tight areas. Their lightweight design also enhances portability, contributing to better overall system design. However, the magnet materials used can be sensitive to temperature fluctuations. Users need to be aware of operating conditions to avoid performance degradation. Such considerations are crucial for long-term efficiency and reliability in demanding environments.

Permanent Magnet (PM) synchronous motors are widely used in various industrial applications. These motors offer high efficiency and reliability. According to a recent industry analysis, the global market for PM synchronous motors is projected to reach $28 billion by 2027. This growth is driven by their increasing adoption in automation and renewable energy sectors.

Many industries utilize PM synchronous motors for specific tasks. In manufacturing, they power conveyor systems and robotic arms. These motors also find applications in electric vehicles, providing torque and efficiency. However, implementing PM motors requires careful consideration of operational requirements and system compatibility. Misalignment in system design can lead to inefficiencies.

Energy savings are significant. Reports indicate that PM synchronous motors can reduce energy consumption by up to 30%. Such savings can boost operational budgets. Still, maintenance strategies must be refined. Regular checks are crucial to ensure optimal performance. Without these, even the most advanced motor can suffer. Awareness of potential issues in modeling can prevent costly downtimes and enhance system lifespan.

Proper maintenance of Permanent Magnet (PM) motors is crucial for their optimal performance. Studies reveal that regular upkeep can increase lifespan by 25%. One essential aspect is to frequently check the rotor alignment. Misalignment can cause vibrations, leading to premature wear. An alignment tolerance of 0.01 mm is often recommended.

Another vital maintenance task is monitoring the temperature. PM motors typically operate well under 120°C. Exceeding this limit can lead to magnetic degradation. A comprehensive thermal management plan is necessary. Routine inspections of cooling systems help prevent overheating, which can be costly.

Additionally, bearings require close attention. Regular lubrication is vital to minimize friction and wear. Insufficient lubrication can reduce efficiency by up to 10%. It's crucial to document maintenance activities. This practice helps track issues over time. Addressing small problems early can prevent larger failures. These detailed practices ensure that PM motors run smoothly and efficiently.

This bar chart illustrates key performance metrics of Permanent Magnet (PM) Synchronous Motors, including Voltage, Current, Efficiency, Torque, and Speed. Understanding these metrics is essential for maintaining optimal performance of PM motors.