In the rapidly evolving landscape of modern engineering and manufacturing, the selection of a Permanent Magnet Direct Drive Motor (PMDDM) has become a critical decision that can significantly impact efficiency and performance. According to a recent report by ResearchAndMarkets, the global market for direct drive motors is projected to reach USD 12.8 billion by 2025, showcasing a compound annual growth rate (CAGR) of 7.4%. This impressive growth underscores the rising demand for PMDDMs, which are praised for their ability to deliver high torque at low speeds while minimizing energy losses. However, with the myriad of options available, choosing the right PMDDM can be daunting.

This blog will explore five essential tips to guide you through the selection process, ensuring that you make an informed decision that enhances both operational efficiency and sustainability in your applications.

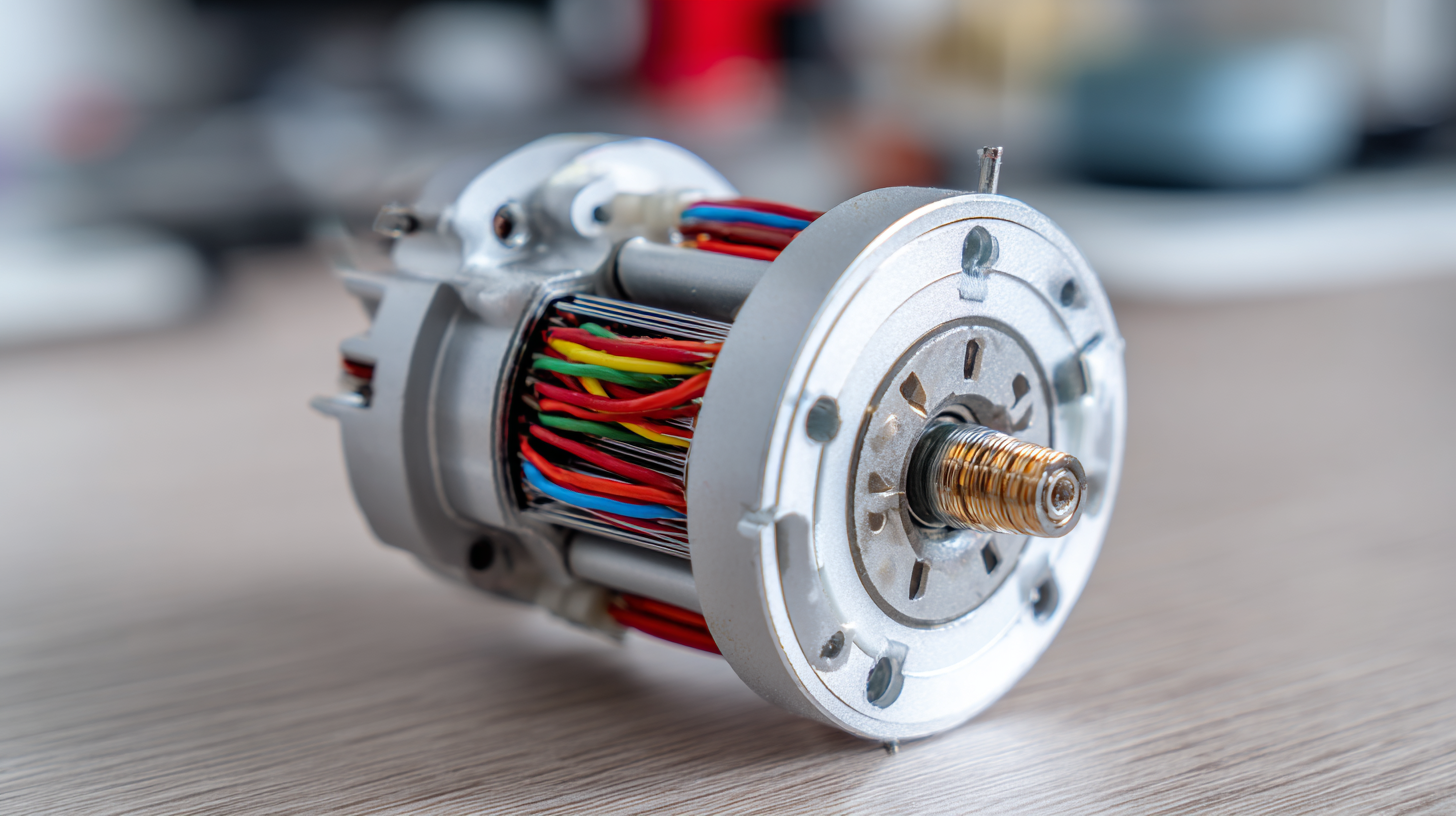

Permanent magnet direct drive motors (PMDDMs) are gaining popularity due to their efficiency and performance in various applications. Understanding the basics of these motors is crucial for making informed decisions when selecting one for your project. A PMDDM utilizes permanent magnets in its rotor, eliminating the need for brushes and reducing maintenance costs. This design allows for precise control and higher torque at lower speeds, making them ideal for robotics, electric vehicles, and industrial machinery.

One of the key advantages of PMDDMs is their compactness and lightweight nature. With fewer moving parts compared to traditional motors, they not only save space but also enhance reliability. Additionally, their energy efficiency leads to lower operational costs over time. When considering a PMDDM, it’s important to evaluate parameters such as torque, speed range, and compatibility with your existing systems. Understanding these fundamentals will aid you in choosing the most suitable motor that meets your specific needs and maximizes the performance of your applications.

When selecting a permanent magnet direct drive motor, understanding the key factors in motor sizing and specifications is crucial for optimizing performance and efficiency. One of the primary considerations is the motor’s torque and speed requirements. Determine the desired application parameters to ensure the motor can deliver the necessary torque at the required RPM. Precision in these calculations will help avoid underperformance or overloading, which can lead to decreased lifespan and operational efficiency.

Another vital factor to consider is the motor's efficiency rating. Different motors operate at varying efficiency levels, which can impact energy consumption and operating costs. Look for motors designed with high-efficiency standards to reduce energy loss during operation. Additionally, consider the thermal characteristics of the motor; adequate cooling and the ability to dissipate heat effectively are important for maintaining performance during prolonged use. Evaluating these factors will ensure you select a motor that not only meets your technical specifications but also supports long-term sustainability and cost-effectiveness in your application.

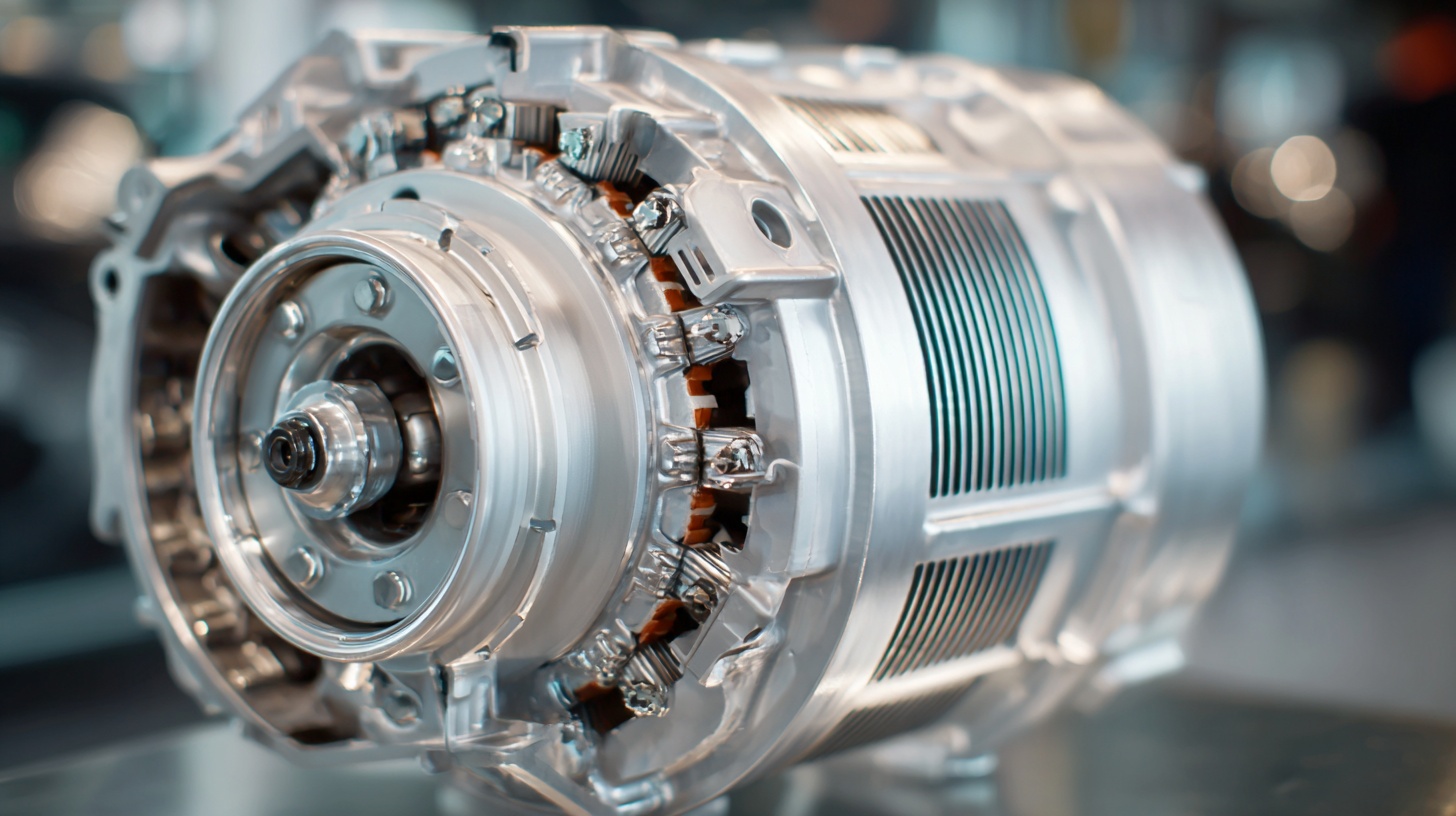

When selecting a permanent magnet direct drive motor (PMDDM), evaluating efficiency is crucial for optimizing performance. One critical performance parameter is the motor's efficiency rating, typically expressed as a percentage of input power converted to useful output power. According to the International Electrotechnical Commission (IEC), high-quality PMDDMs can reach efficiencies exceeding 95%, significantly reducing energy consumption compared to traditional motors. This efficiency not only lowers operational costs but also minimizes the carbon footprint, making them an environmentally friendly choice.

Another essential performance metric is the torque-to-weight ratio, which directly impacts the motor's responsiveness and overall efficacy. A study published by the Electric Power Research Institute (EPRI) indicates that PMDDMs boast torque-to-weight ratios ranging from 2 to 6 Nm/kg, outperforming standard induction motors that generally offer ratios below 2 Nm/kg. This advantage allows for more compact designs and greater flexibility in applications, especially in industries that require high precision and reliability, such as robotics and electric vehicles. By focusing on these parameters, you can ensure that your choice of a PMDDM aligns with both your efficiency and performance needs.

| Parameter | Description | Recommended Value | Measurement Method |

|---|---|---|---|

| Efficiency | Ratio of output power to input power, indicating motor performance | > 90% | Tests under load conditions |

| Torque | The rotational force generated by the motor | Depending on application, typically > 5 Nm | Torque measurement devices |

| Speed | The rotational speed of the motor, measured in RPM | 1000-3000 RPM | Tachometers |

| Power Rating | The maximum power output of the motor, typically in Watts | 500 - 5000 W | Power analyzers |

| Cooling Method | The method used to dissipate heat from the motor | Air-cooled or liquid-cooled | Thermal imaging or temperature sensors |

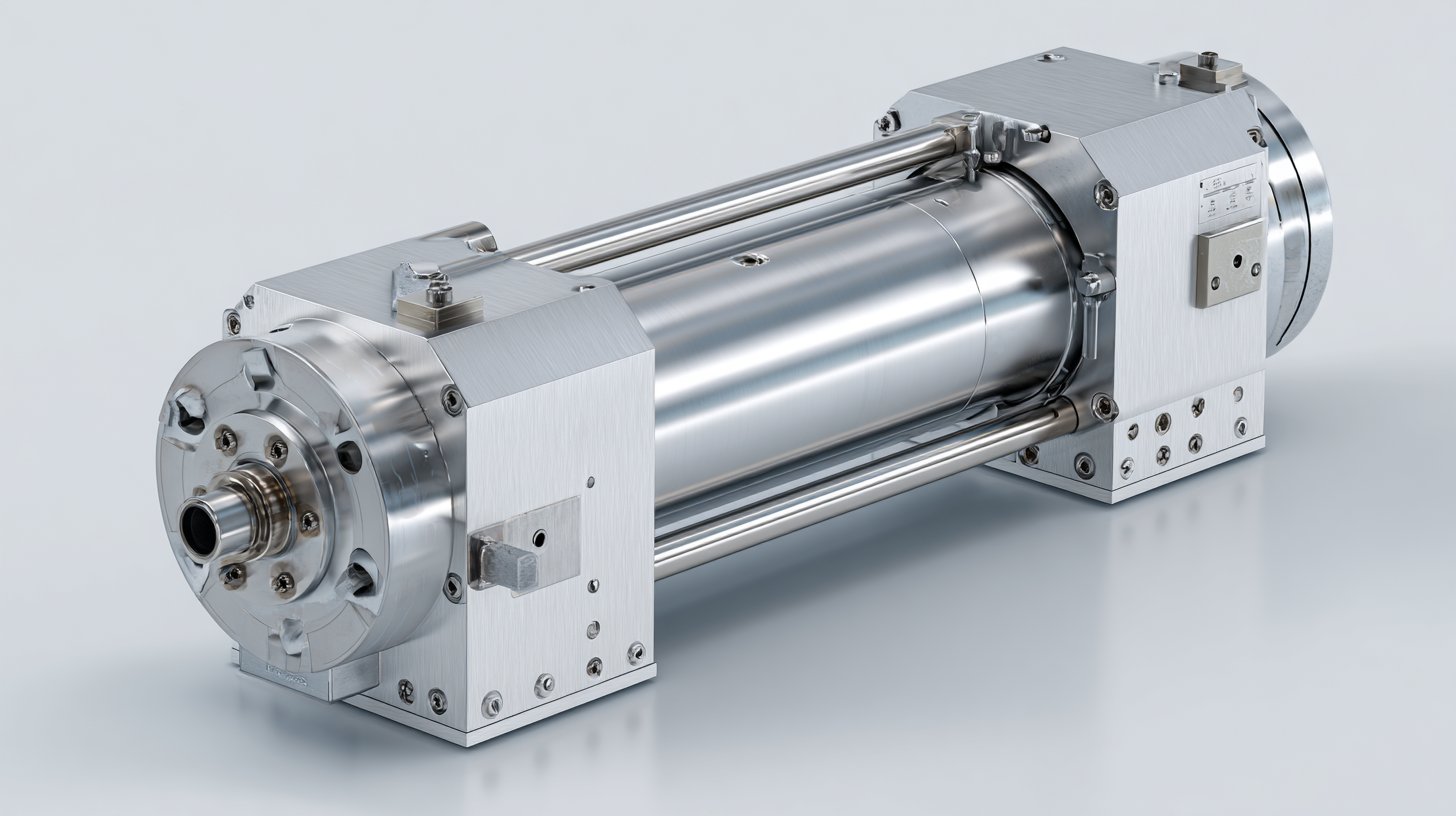

When selecting the right permanent magnet direct drive motor, understanding the specific application requirements is fundamental. Every application has unique demands regarding

speed, torque, and operational environment. For instance, an application

requiring high torque at low speeds will necessitate a different motor design compared to one that operates at high speeds. Analyzing

these parameters ensures that the selected motor will provide optimal performance and efficiency, ultimately leading to a successful operation.

Additionally, considering factors such as the physical space available for installation and potential environmental conditions can significantly influence your choice.

Motors subjected to extreme temperatures, humidity, or dust will require different enclosures or materials for durability. Furthermore, the expected load and duty cycle of the motor

must align with its rated capabilities to prevent premature failure. Therefore, thoroughly evaluating these application requirements not only aids in selecting the right permanent magnet direct drive motor but also enhances reliability and extends the lifespan of the entire system.

When selecting a Permanent Magnet Direct Drive Motor (PMDDM) for your project, the balance between cost and quality is paramount. According to a report from Transparency Market Research, the global market for PMDDMs is projected to grow significantly, driven by their efficiency and reliability. However, the challenge remains in choosing a motor that not only meets your performance requirements but does so within a budget. While cheaper models may initially seem attractive, they often compromise on critical factors like durability and efficiency, leading to higher long-term operational costs.

One key consideration is the motor’s efficiency rating. A study by the International Energy Agency (IEA) found that high-efficiency motors can reduce energy consumption by up to 30% compared to standard models. This translates into significant savings and a quicker return on investment, justifying the higher upfront cost. Additionally, investing in quality often means better technical support and longer warranties, which are invaluable for minimizing downtime in industrial applications. Thus, while it may be tempting to opt for a low-cost option, understanding the long-term implications of such a decision is crucial for the overall success of your project.