When it comes to selecting the right Roll Mill Sleeve, understanding your specific needs is crucial. Industry expert John Smith states, "Choosing the right sleeve can significantly impact your operational efficiency." This highlights the importance of making an informed decision.

Roll Mill Sleeves are vital components in various manufacturing processes. They affect product quality and overall performance. A sleeve that does not match your equipment can lead to complications and inefficiencies. Many professionals overlook this when making their purchases. The result? Increased production costs and wasted resources.

Consider the material, size, and compatibility of the Roll Mill Sleeve. Each detail matters. You might find it easy to rush this decision. Avoiding this can prevent future headaches. It's about more than just buying a part—it's about investing in quality. Think carefully about your choice.

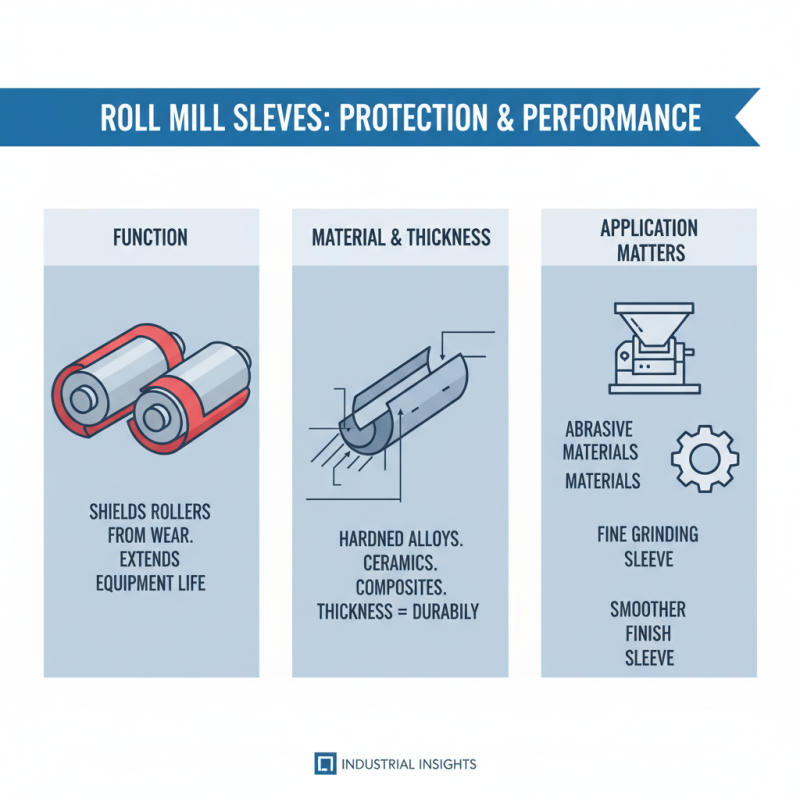

Roll mill sleeves play a crucial role in the operation of a roll mill. They are designed to protect the rollers from wear and tear. The material and thickness of the sleeve can affect its durability and performance. Different applications require different sleeve characteristics. For example, a sleeve used for handling abrasive materials may need a harder surface.

Understanding the various functions of roll mill sleeves is essential. They not only safeguard the rollers but also influence product quality. A well-chosen sleeve minimizes contamination risks. However, choosing the wrong one can lead to inefficiency and increased maintenance costs.

It's worth noting that sometimes, users overlook sleeve compatibility with their specific needs. Some may choose based solely on price. This approach can lead to regrettable results. Before making a decision, carefully consider the specific requirements of your milling process. Knowing your material and operational environment is vital.

Choosing the right roll mill sleeve is crucial for optimal performance.

Consider the material. Different applications require different materials.

For example, some processes may need tougher sleeves while others prioritize flexibility.

It’s essential to match the material to your specific use case.

Another factor is the size of the sleeve.

Ensure that it fits your equipment properly. A sleeve that’s too loose could result in inefficiencies.

Conversely, one that’s too tight may cause unnecessary wear and tear. Measure carefully.

Often, users overlook this detail, which can lead to frustration later.

Finally, think about the design and texture.

These can impact the grinding efficiency. A smooth surface can reduce friction.

However, a textured design may enhance material handling.

Often, the choice comes down to trial and error.

Balancing these factors requires careful consideration and sometimes, reflection on past choices.

Make sure to evaluate your needs regularly.

When selecting a roll mill sleeve, it’s crucial to consider the material types available. Each material offers specific advantages for different applications. Common materials include polyurethane, rubber, and steel.

Polyurethane is known for its durability in abrasive environments. It offers chemical resistance while maintaining flexibility. Rubber sleeves, on the other hand, provide excellent grip and shock absorption. They are ideal for softer materials and less aggressive applications.

Steel sleeves are robust and used in high-load situations. They can withstand extreme forces but may create friction issues in certain contexts. A recent industry report highlighted that nearly 35% of mills face challenges with wear and tear on their sleeves. This suggests that material choice directly impacts maintenance costs and operational efficiency. It's important to evaluate not only the current needs but also future requirements.

Understanding the specific application is essential. For example, in the food industry, compliance with sanitation standards is vital. Meanwhile, in manufacturing, the focus may be on tensile strength. A poorly chosen sleeve can lead to inefficiencies and increased downtime. Therefore, proper research into the material’s properties is necessary for optimal performance.

Choosing the right roll mill sleeve requires careful consideration of sizing and compatibility. A well-fitted sleeve optimizes the efficiency of your mill. It ensures consistent production rates and reduces downtime. According to industry data, improper sizing can lead to a 15% drop in operational efficiency. This underlines the importance of selecting the right dimensions.

Compatibility is also critical. Ensure the sleeve material aligns with the application needs. Materials like rubber and polyurethane have different properties. Each has its strengths and weaknesses. For instance, rubber may offer better elasticity, while polyurethane provides greater durability. Make sure to assess your specific processing requirements well. A mismatch can compromise product quality.

Regularly revisit your equipment alignment. Periodic checks could prevent production disruptions. Many facilities overlook this. They assume the initial setup remains effective. Tightening specifications could enhance performance. Accurate data collection on usage patterns can inform these adjustments. Recognizing the need for reflection is vital in making improvements. It is a continuous process.

This bar chart illustrates the compatibility ratings for different types of roll mill sleeves. A higher rating indicates a better fit for equipment needs, helping you make informed decisions when choosing the right sleeve for your application.

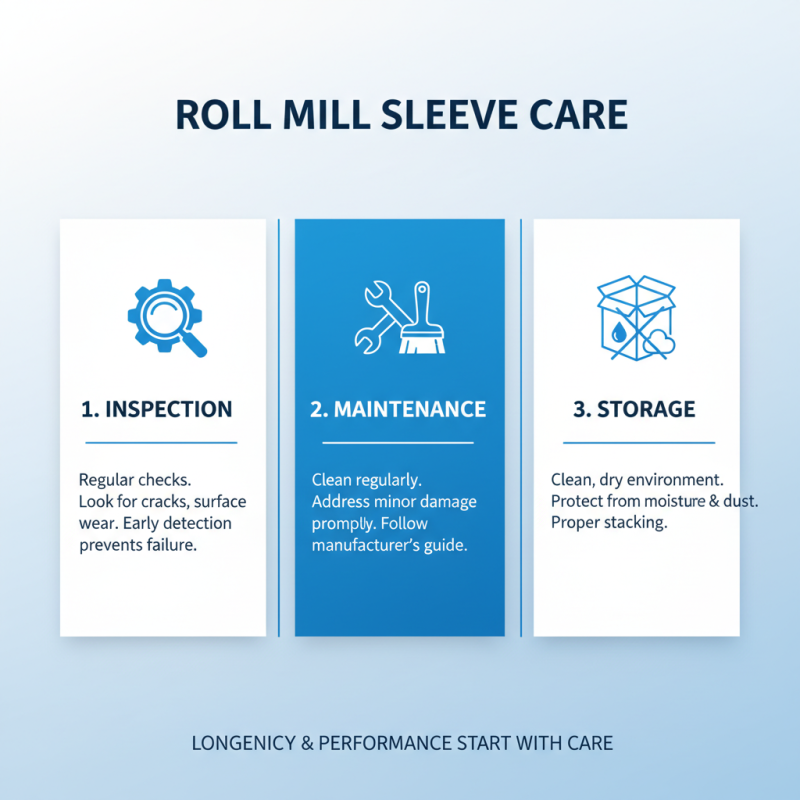

Maintaining roll mill sleeves is crucial for longevity and performance. Regular inspection helps identify wear and tear early. Look for signs like cracks and surface degradation. These can compromise functionality. Simple checks can guide your maintenance routine. Don’t underestimate the importance of proper storage. Storing sleeves in a clean, dry environment keeps them in good condition.

Cleaning is another vital aspect. Use appropriate solvents to remove residues. Avoid harsh chemicals that could damage the material. A soft brush can effectively clean small crevices too. Regular lubrication of moving parts reduces friction, aiding in smoother operation. Consider the lubricants used; they should be compatible with the sleeve material.

Overheating is a concern during operation. It can lead to rapid wear. Monitor operating temperatures closely. Excessive heat can be mitigated through proper cooling systems. If damage occurs, replace the sleeve promptly to maintain overall machine performance. Understanding these maintenance tips encourages more efficient and reliable operation of roll mills.