In the world of industrial manufacturing, choosing the right Ceramic Composite Roller Sleeve can significantly impact productivity and efficiency. Industry experts estimate that the right sleeve can enhance operation lifespan by up to 30%. However, the selection process can be overwhelming, given the numerous options available.

Dr. Emily Tran, a renowned expert in composite materials, emphasizes, “A well-chosen Ceramic Composite Roller Sleeve can transform your machinery's performance.” Her insight underscores the importance of understanding your specific needs. Factors include the material properties, operating environment, and cost-effectiveness.

While many brands offer high-quality options, not all are suitable for every application. You might face challenges in balancing performance and budget. Evaluating your operational demands is crucial, yet often overlooked. The decisions made now could lead to costly errors later. Thus, taking the time to research and reflect is vital for optimal results.

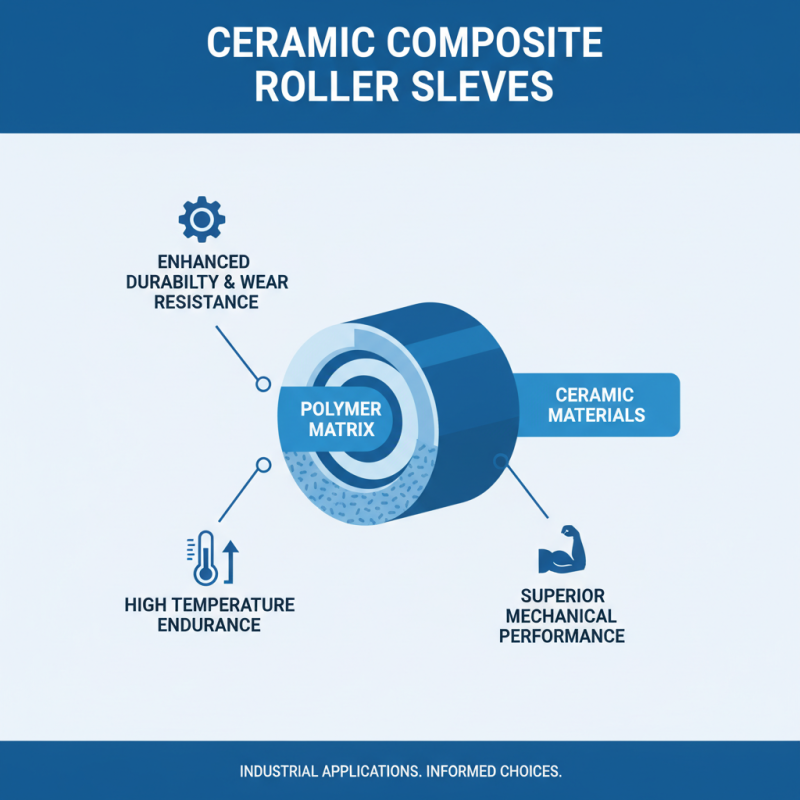

Ceramic composite roller sleeves are crucial for various industrial applications. Understanding their basics helps in making informed choices. These sleeves combine ceramic materials with a polymer matrix. This combination enhances durability and resistance to wear. They endure high temperatures and provide excellent mechanical performance.

When selecting a ceramic composite roller sleeve, consider your specific needs. Assess the load capacity and temperature range of your application. Some sleeves may not perform well under extreme conditions. Evaluate the environment where they will be used. Dust, moisture, and chemical exposure all play a role in longevity.

It is essential to reflect on the cost versus performance ratio. A cheaper option might save money initially but can lead to frequent replacements. This could increase overall costs in the long run. Not all sleeves fit every application perfectly, and sometimes, a trial-and-error approach is necessary. Think about maintenance, too. A good roller sleeve requires minimal upkeep, saving time and resources.

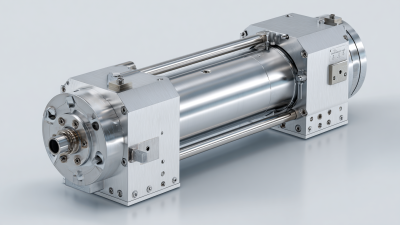

Ceramic composite roller sleeves have gained popularity in various industries due to their unique advantages. These roller sleeves boast superior durability compared to metal or plastic alternatives. According to recent industry reports, ceramic composites can withstand extreme temperatures and pressures, making them ideal for demanding applications. Their resistance to wear and tear extends the lifespan of machinery, ultimately reducing maintenance costs.

One significant benefit of ceramic composite roller sleeves is their lightweight nature. This feature can lead to lower energy consumption during operation. Many facilities have reported energy savings of up to 15% after switching to these roller sleeves. It’s crucial to weigh these benefits against potential higher initial costs.

Tips: When selecting a ceramic composite roller sleeve, consider its intended application. Ensure it meets the specific temperature and load requirements for your equipment. Often, users overlook compatibility, leading to unexpected issues. Regular inspections are necessary to detect wear early, which can avert larger problems later on.

| Feature | Description | Advantages |

|---|---|---|

| Material Quality | High-grade ceramic and composite materials. | Enhanced durability and wear resistance. |

| Weight | Lightweight design for easy handling. | Reduced fatigue during operation. |

| Temperature Resistance | Can withstand high temperatures without deforming. | Increased performance in heated environments. |

| Surface Finish | Smooth finish for optimal performance. | Minimized friction, leading to extended lifespan. |

| Cost-effectiveness | Affordable pricing without compromising quality. | Long-term savings due to lower replacement frequency. |

Choosing the right ceramic composite roller sleeve can significantly impact your operations. Understanding specific factors is essential to making an informed decision. The material quality is crucial. High-quality ceramic composites provide durability and resistance to wear. According to industry reports, the right material can increase product lifespan by up to 40%.

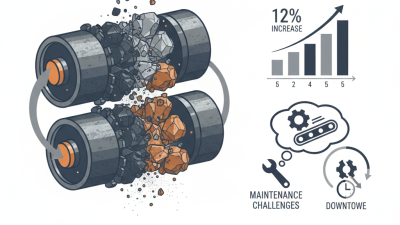

Next, consider the roller sleeve's size and fit. A sleeve that does not fit properly can lead to inefficiencies. Studies reveal that improper sizing can lead to a 15% increase in waste during production. It's essential to measure the roller axis and select an appropriate diameter.

Another factor is the operating environment. Ceramic sleeves perform differently under various conditions. For instance, high-temperature settings may require special coatings. Monitoring performance and adjusting conditions can reveal flaws in initial choices. A report suggests that 30% of users regret not considering environmental factors before selection. Thus, taking time to evaluate needs is vital for long-term efficiency.

When selecting a ceramic composite roller sleeve, it's essential to understand the different types of materials available. Ceramic composites can vary significantly in composition and performance. Common materials include alumina, zirconia, and silicon carbide. Each offers unique benefits for specific applications.

Alumina is well-regarded in industries that require high wear resistance. It contains a high volume of ceramic particles. This allows for better durability, especially under mechanical stress. According to the American Ceramic Society, alumina can achieve a hardness of about 9 on the Mohs scale. However, it may not be suitable for extreme temperature applications.

Zirconia, while more expensive, offers excellent toughness. It can withstand impact better than alumina. In a study by the International Journal of Advanced Manufacturing Technology, zirconia ceramic composites showed 30% more resistance to crack propagation than alumina counterparts. However, this comes at a cost; the manufacturing process requires more resources and time.

Silicon carbide is another alternative. It ranks high in thermal conductivity and is also highly resistant to thermal shock. However, its brittleness can make it prone to fractures. A report from the Ceramic Engineering Society highlights that silicon carbide, while strong, needs careful handling during installation. Making the right choice hinges on understanding these trade-offs, reflecting the balance between performance and durability.

Ceramic composite roller sleeves have a wide range of applications across various industries. In manufacturing, these sleeves are essential for processes that require high durability and resistance to wear. Studies indicate that facilities using ceramic composite materials can reduce maintenance costs by up to 30%. This reduction in downtime is critical in industries where precision and efficiency are paramount.

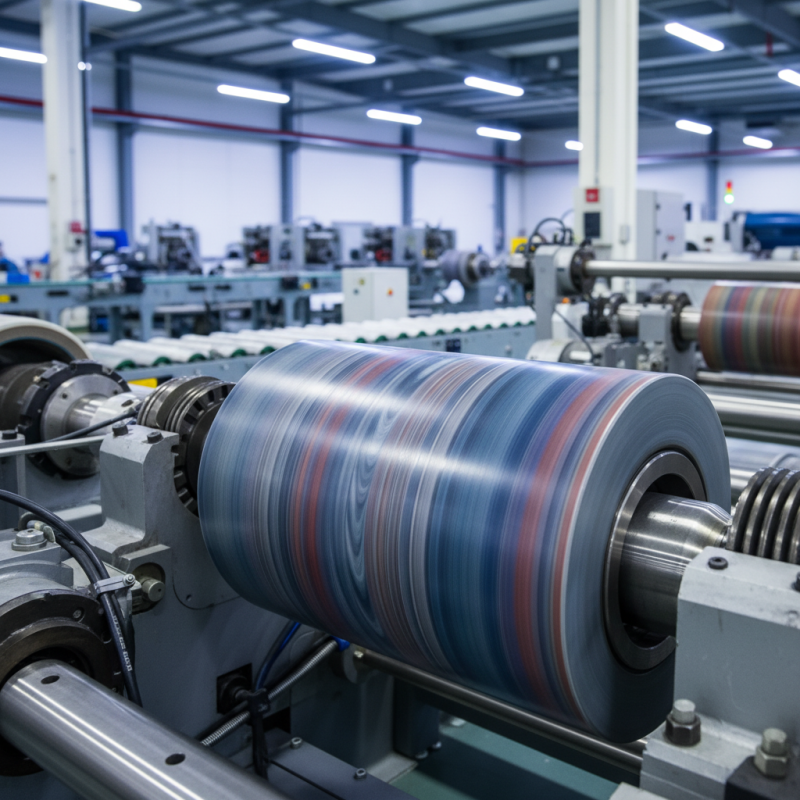

Printing and packaging also benefit significantly from ceramic composite roller sleeves. The ability to withstand high temperatures and pressures makes them ideal for these environments. Data shows that companies using these materials have reported a 20% increase in operational efficiency. This boost can lead to better product quality and lower rejection rates.

In the food processing sector, hygiene is a priority. Ceramic composite materials can withstand harsh cleaning chemicals without degrading. This quality ensures compliance with safety regulations. However, some users still face challenges with installation. Improper fitting can lead to performance issues. Reflecting on experiences may reveal gaps in installation training. Addressing these gaps can improve overall effectiveness in various applications.