Air Suspension Centrifugal Blower technology is essential for various industrial applications. Its design focuses on optimizing airflow while ensuring energy efficiency. However, many users experience performance issues due to improper settings or maintenance. These challenges can significantly impact productivity.

Understanding the components and functionality of the Air Suspension Centrifugal Blower is vital. When each part works harmoniously, the blower performs at its best. Regular checks can prevent unexpected downtimes. Overlooking small details can lead to inefficiencies that might go unnoticed initially.

In addition, users must recognize that not every Air Suspension Centrifugal Blower is the same. Different environments require tailored adjustments. Ignoring these unique needs can result in subpar performance. Reflecting on past experiences often reveals areas for improvement, bringing long-term benefits.

Air suspension centrifugal blowers play a vital role in various industrial applications. These blowers work by moving air through rapid centrifugal force. This mechanism allows for efficient airflow management in systems like pneumatic conveying and HVAC applications. Reports indicate that these blowers can achieve efficiency ratings of up to 75%. However, this performance varies based on design and operating conditions.

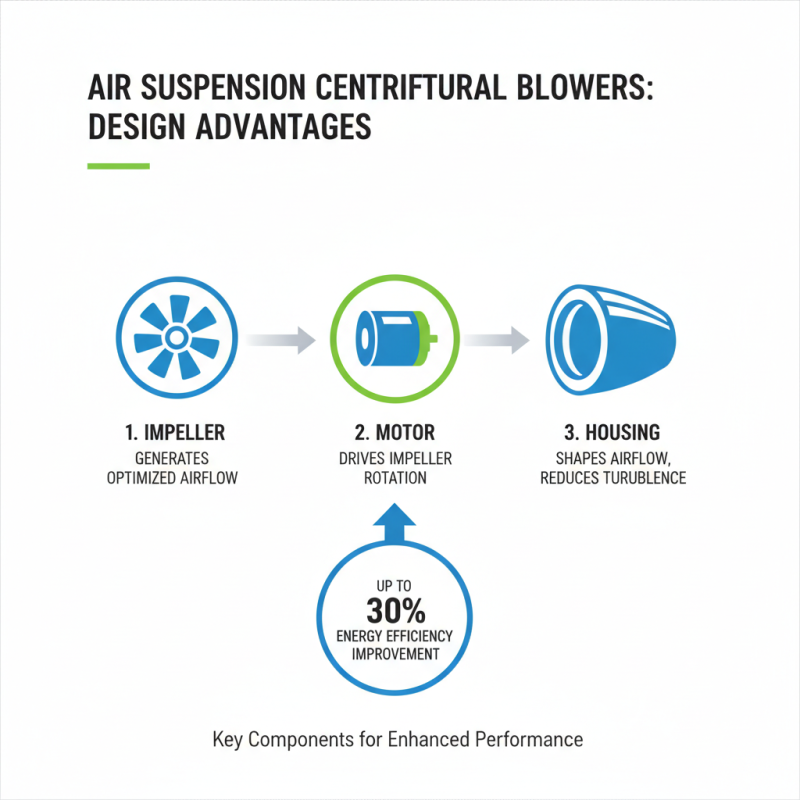

With varied designs, understanding how these blowers function is critical. They typically include an impeller, casing, and a motor. When operated, the impeller spins, allowing air to enter the casing. This creates a pressure differential. Unexpected noise or vibration can imply inefficiency. Regular maintenance is necessary. Some units also require specific environmental conditions to function optimally. Knowing the precise requirements can prevent performance issues.

Users often overlook parameters like inlet temperature and pressure. These factors heavily influence operational efficiency. A rise in inlet temperature can decrease performance by approximately 5% for every 10°C increase. In practical terms, consistent monitoring can mitigate performance drops. Finding the ideal operating conditions boosts overall effectiveness. This approach helps ensure that air suspension centrifugal blowers deliver their best performance.

Air suspension centrifugal blowers offer unique design advantages that enhance their performance. Key components include the impeller, motor, and housing. The impeller generates airflow, while the motor drives its rotation. The housing's design shapes airflow and reduces turbulence, which is crucial for efficiency. According to industry reports, optimizing each of these components can improve energy efficiency by up to 30%.

Tips for enhancing performance involve regular maintenance, which is often overlooked. Keeping the impeller clean can increase airflow and reduce energy consumption. Also, ensure that the motor is properly aligned. Misalignment can cause unnecessary wear and reduce efficiency. Regularly inspecting the housing for leaks is vital. Even small leaks can significantly impact overall performance.

Another point to consider is the selection of the right rotor type. Each rotor design has unique advantages. However, the choice can have a significant impact on airflow stability. Some users may find it challenging to evaluate these options effectively. Understanding the specific application requirements is essential. It’s worth noting that improper setup can lead to decreased performance. Investing time in the setup process can prevent these common pitfalls.

Maintaining centrifugal blowers is crucial for optimal performance. Regular maintenance can prolong the blower's life. One key aspect is to inspect the filters. Clogged filters can decrease efficiency. Clean them often to ensure proper airflow.

Another important tip is to check for leaks. Even small leaks can cause energy loss. Inspect ductwork regularly for any signs of damage. Tighten connections and replace worn parts as needed. Keeping everything sealed helps maintain performance.

Don’t forget about lubrication. Bearings require proper lubrication to function. Inspect lubrication levels monthly. Change oil as recommended to keep components running smoothly. Listen for any unusual noises; they might indicate a problem. Regularly review maintenance records to track patterns and anticipate issues.

Optimizing the performance of air suspension centrifugal blowers is crucial for efficiency. Proper settings can significantly impact airflow and energy consumption. Start by adjusting the pressure settings. Too high pressure can increase wear and tear. Conversely, low pressure means inadequate airflow and inefficiency.

Adjusting the speed control is another key factor. A blower running at the wrong speed may create excess noise or vibrations. Fine-tuning this can enhance performance. Keep an eye on temperature levels too; overheating is a clear indicator of an underlying problem. Regular maintenance checks are essential. They help identify issues before they escalate.

It's also important to reflect on your system's specific needs. Sometimes, even minor adjustments offer huge benefits. Take time to analyze your current setup. Are you getting the airflow you need? Can small tweaks make a difference? Continuous evaluation is vital for optimizing performance.

Air suspension centrifugal blowers are essential tools in various applications. However, they can encounter common issues that affect performance. One frequent problem is airflow restriction caused by blockages. Dust and debris can accumulate in filters and ducts. Regular cleaning and maintenance can help prevent these restrictions.

Vibrations can also occur, signaling potential problems. These vibrations may stem from unbalanced components or misalignment. Identifying and correcting these issues is vital to avoid further damage. Inspecting the motor and fan assembly can reveal underlying concerns that need attention.

Another issue is irregular noise, which can indicate wear or damage. Pay attention to sudden changes in sound. Anomalies can be a sign that maintenance is overdue. Additionally, monitoring temperature changes can be crucial. Overheating can lead to premature failure. Regular checks can ensure optimal performance and longevity.