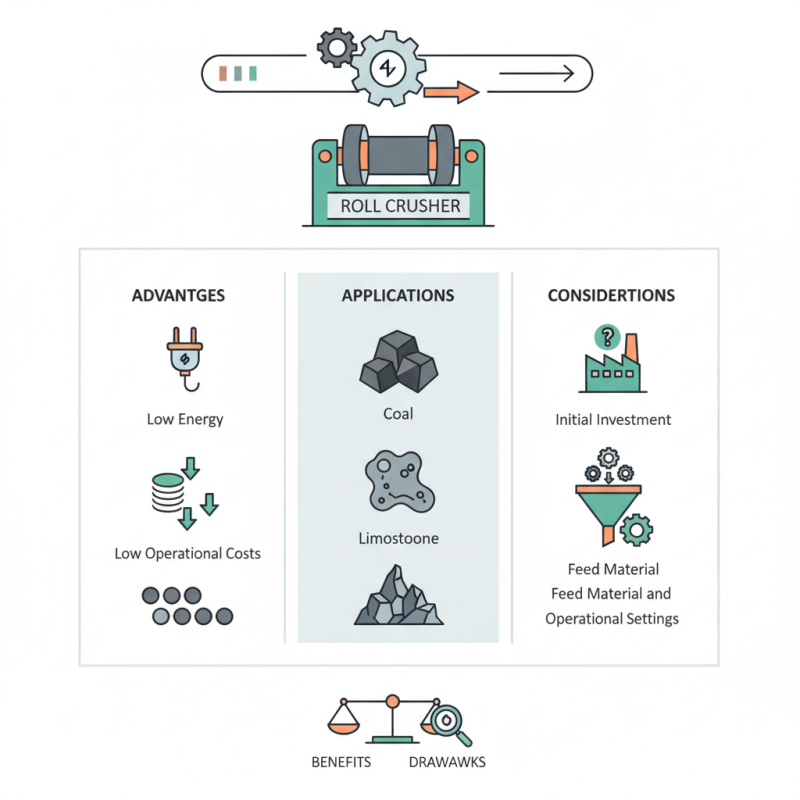

In the industrial sector, efficiency and reliability are paramount. The Roll Crusher stands out as a key player in size reduction processes. Renowned expert Dr. John Smith, a leader in material processing, once stated, “The Roll Crusher offers unique capabilities that enhance productivity.”

This machine excels in crushing materials like coal, clay, and limestone. It operates with minimal energy consumption. Users often highlight its low operational costs as a significant benefit. However, the effectiveness of a Roll Crusher can vary. Factors like feed material and operational settings play crucial roles.

The machine's design allows for a uniform particle size, making it suitable for various applications. Nonetheless, some may find the initial investment challenging. It’s essential to weigh the benefits against potential drawbacks. Choosing a Roll Crusher requires careful consideration to maximize advantages in the production line.

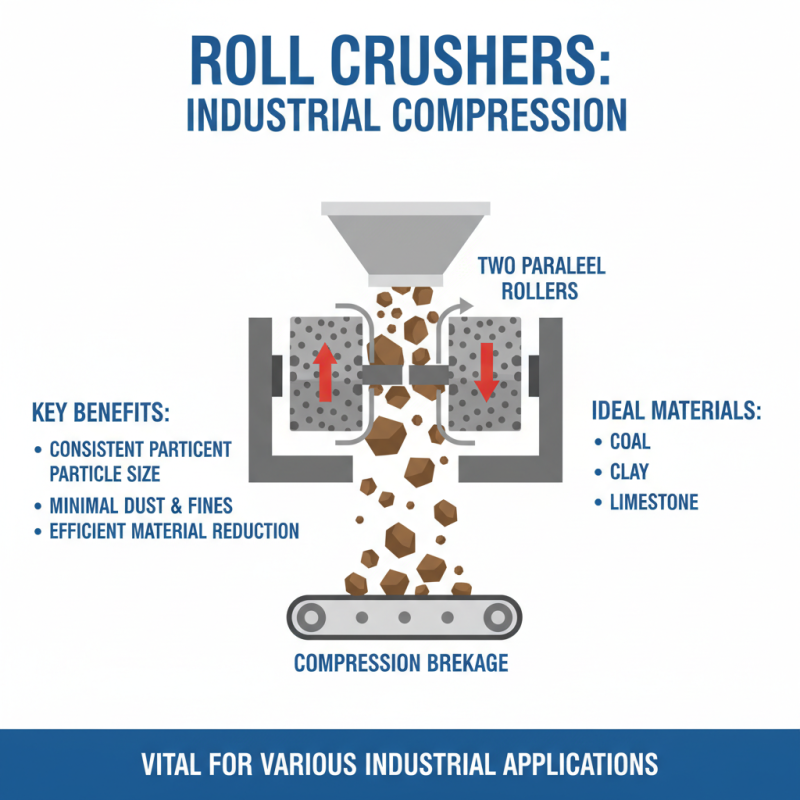

Roll crushers are vital in various industrial applications. They effectively break materials through compression. Ideal for materials like coal, clay, and limestone, they provide consistent particle sizes. Their design includes two parallel rollers that rotate in opposite directions. This action crushes the materials between them, generating minimal dust and fines, which is beneficial for many industries.

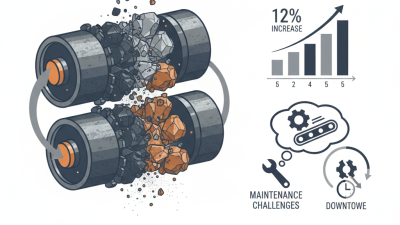

One advantage of roll crushers is their energy efficiency. They utilize less power compared to other machines. This efficiency can lead to reduced operational costs, which many companies find appealing. However, users might face challenges, such as wear on the rollers over time. Regular maintenance is necessary to keep them functioning at their best.

Tip: Monitor the roller condition regularly. A small issue can lead to bigger problems. In some cases, the crush size might be inconsistent, depending on the material's hardness. Adjusting the gap between rollers can help solve this problem. With proper care, roll crushers can greatly enhance production processes in various sectors.

Roll crushers play a crucial role in various industrial applications. They are designed to crush materials like coal, clay, and limestone. One key feature of roll crushers is their simple structure, which allows for easy maintenance. They have a compact design that saves space, making them ideal for facilities with limited room.

The mechanism of roll crushers involves using two heavy rollers to crush the material. When materials are fed into the machine, they pass between these rollers. The pressure applied reduces the material size effectively. According to industry reports, roll crushers can achieve a size reduction ratio of 4:1, making them efficient for many applications.

Tips: Always ensure regular maintenance of the rollers. This prevents breakdowns and prolongs lifespan. Regularly check for wear and tear to address issues before they escalate.

Another advantage of roll crushers is their energy efficiency. They consume less energy compared to other crushing equipment. This makes them a cost-effective option in the long run. However, one must consider the limitations. Roll crushers work best with soft to medium-hard materials. They may struggle with very hard materials, leading to potential inefficiencies.

Tips: Monitor the feed material's hardness closely. This helps in determining if a roll crusher is the right choice. Be aware of its limitations to maximize efficiency.

| Feature | Description | Benefits |

|---|---|---|

| High Reduction Ratio | Roll crushers can crush materials to a desired size with a high reduction ratio. | Increased efficiency in size reduction processes. |

| Low Noise and Vibration | Operates quietly compared to other types of crushers, with minimal vibrations. | Improves workplace safety and comfort. |

| Versatility | Can handle various materials, including minerals and soft ores. | Flexibility in application across different industries. |

| Easy Maintenance | Simple design leads to easier access for maintenance and repairs. | Reduces downtime and operational costs. |

| Energy Efficiency | Uses less energy when compared to other crushing mechanisms. | Lower operating costs and reduced environmental impact. |

Roll crushers are valuable in many industrial applications for reducing material size. They efficiently crush a variety of materials, including soft minerals and medium-hard rocks. Their design allows for uniform particle size, which is critical in processes like milling and compaction.

One key advantage is the ability to achieve a consistent particle size. This is essential for industries where precision matters, like pharmaceuticals or food production. The gentle crushing action leads to minimal degradation of the material. However, this process does come with its challenges. If not monitored correctly, the output size can vary, leading to inconsistencies.

Energy efficiency is another benefit. Roll crushers consume less power compared to other crushing equipment. They operate quietly and produce less dust, making them more environmentally friendly. Despite these advantages, they may not be suitable for very hard materials. Each application requires careful consideration of the material properties to avoid inefficiencies. Balancing cost-effectiveness and performance is vital here.

This chart illustrates the key advantages of using roll crushers in industrial applications, highlighting their efficiency, energy consumption, maintenance needs, product size control capabilities, and versatility in material size reduction processes. Each advantage is rated on a scale from 1 to 10, showing their relative benefits in industrial settings.

Roll crushers are highly valued in industrial applications for their cost-effectiveness. They excel in size reduction tasks, making them ideal for various materials. By operating with minimal energy consumption, they help organizations save on operational costs. This is critical for industries looking to improve their profit margins.

One key feature of roll crushers is their ability to produce uniform product sizes. Having consistent dimensions can reduce waste and increase efficiency in downstream processes. However, achieving this uniformity requires meticulous adjustments and monitoring. It's not always simple, as the wrong settings can lead to inconsistent outputs.

Tips: Regular maintenance is essential. Ensure that the rolls are kept clean and free from buildup. This helps maintain performance and longevity. Always monitor the wear and tear of components. It's better to replace them early than to face unexpected downtimes later. Lastly, experiment with different materials to refine your processing techniques. This exploration might reveal new efficiencies.

Roll crushers play a vital role across various industries due to their efficiency and versatility. They are widely used in mining, coal, and recycling industries. According to a recent market research report, the global roll crusher market is expected to grow by over 4% annually. This growth reflects the increasing demand for rock and mineral processing equipment.

In the mining sector, roll crushers help in reducing the size of ores for further processing. They efficiently crush materials while minimizing dust and noise. For instance, the coal industry utilizes roll crushers to produce uniform coal sizes for power generation. In the recycling sector, they excel in crushing materials like plastic, metal, and glass. This process not only facilitates recovery but also promotes sustainability.

However, roll crushers are not without limitations. They may struggle with very hard or sticky materials. This could lead to higher operational costs and downtime for maintenance. Additionally, their capacity can be hindered if not appropriately sized for the application. Despite these challenges, roll crushers remain an essential tool in many industries due to their ability to provide uniform particle size and reduce material handling costs.