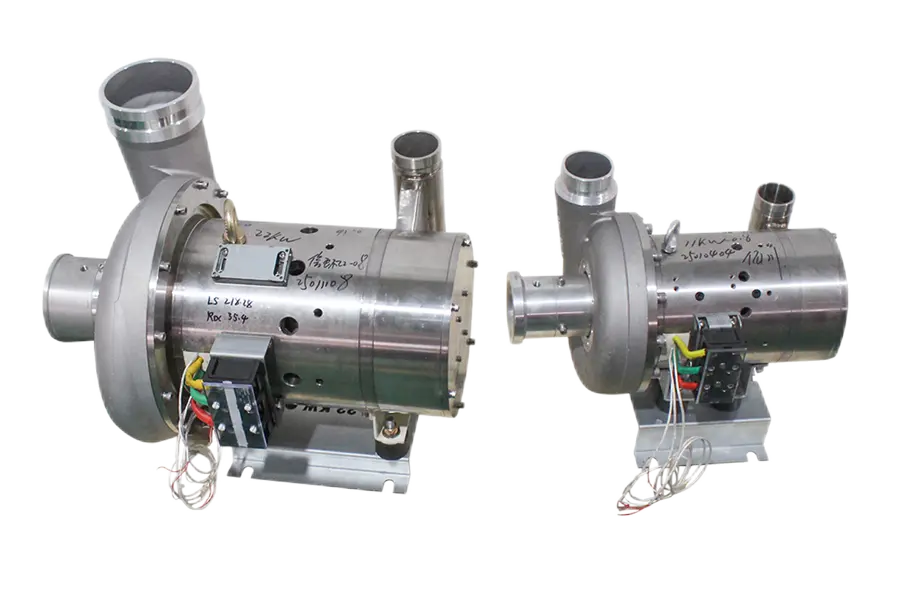

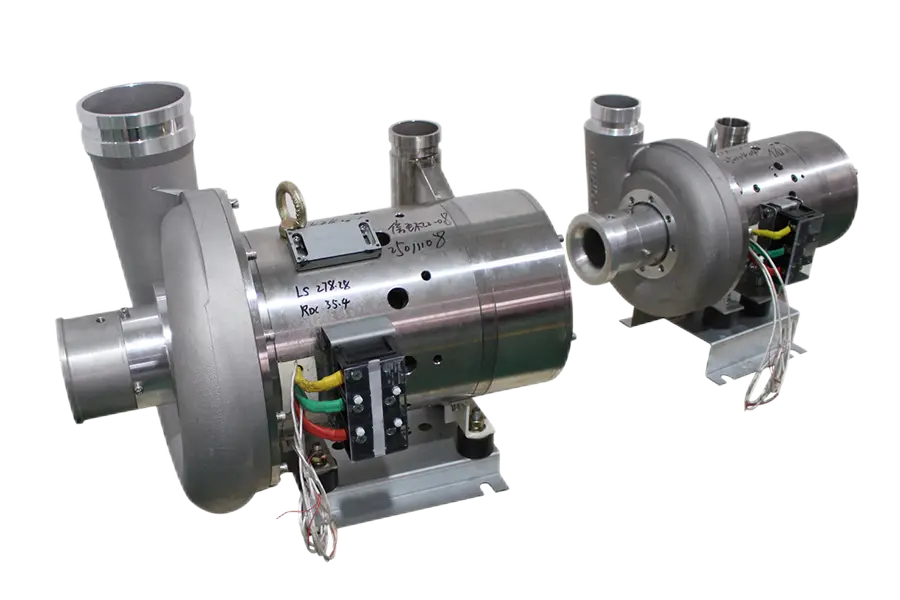

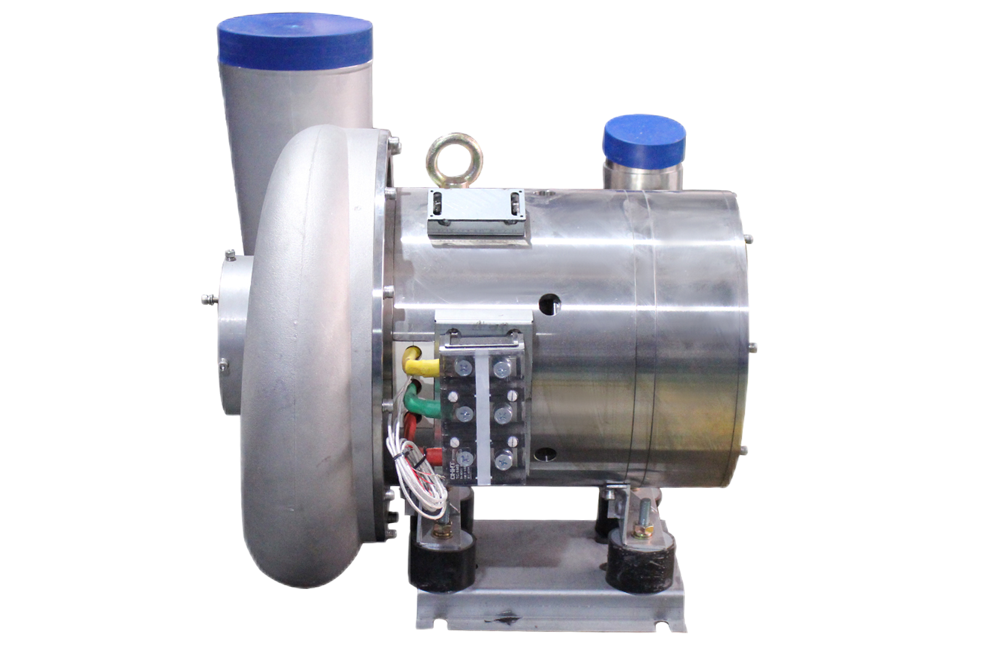

Air Suspension High-Speed Permanent Magnet Synchronous Motor

-

- Air Suspension Bearing Technology: When the rotor rotates at high speed, an air dynamic pressure is naturally generated between the rotor and the foil structure bearing. The air dynamic pressure bearing is a non-contact bearing that uses air as a lubricant, ensuring 100% oil-free operation. With zero friction and no power loss during operation, this technology is highly mature and has a simple structure. Without a grease lubrication system, it can reach a maximum speed of 100,000 RPM, demonstrating excellent high-speed operation capabilities, stability, and strong load-bearing capacity. The bearing structure effectively suppresses rotor vibration, with a minimal amplitude of less than 20μm, resulting in low noise. The special coating technology effectively reduces start-stop wear, allowing for more than 20,000 start-stop cycles.

-

- Direct Drive with Three-Element Flow Impeller: Just like the maglev motor, it directly drives the three-element flow impeller, eliminating the speed-increasing gear structure and improving transmission efficiency.

- Rotor with Rare Earth Permanent Magnet Excitation: The use of rare earth permanent magnets for rotor excitation contributes to the high efficiency of the motor.

-

- Unique High-Strength Carbon Fiber Binding Technology: This technology, after a 115% overspeed test, ensures the reliability of the rotor permanent magnets at high speeds.

-

Optimal System Design: The electromagnetic, aerodynamic, and frequency conversion drive characteristics are matched to achieve the best overall system performance.In conclusion, whether you choose our magnetic levitation or air suspension high-speed permanent magnet synchronous motors, you are investing in cutting-edge technology that offers high efficiency, reliability, and advanced performance for your industrial applications.